Custom Plastic Injection Molding Service in China

From 1 to 1+ Million Parts. We Scale With You. Your one-stop manufacturer for design, prototype, precision molding, surface finishing, and final assembly.

- ISO 9001/13485/14001 Certified

- FDA/UL Compliant Materials

- In-House R&D Team

- 100k+ Daily Output Capacity

What is Plastic Injection Molding Service

Plastic injection molding involves heating and melting plastic into a fluid. This fluid is then injected into a pre-made mold using high pressure. Once the plastic cools and solidifies, the mold is opened to create a precise and complex plastic part. Numerous plastic products, from small mobile phone cases to large automotive components, are manufactured using this process.

YG transforms this process into a solution. We do more than just “parts manufacturing”—we optimize your design for manufacturability, select materials that comply with international standards (FDA, RoHS), and deliver parts with tight tolerances (±0.001mm) on time, whether you need 1 prototype or 100,000 production units.

From Concept to Completed Product

Custom Plastic Injection Molding Solutions

Engineering-driven manufacturing for complex geometries. From tight-tolerance functional parts to multi-material consumer products, we deliver consistent quality at scale.

01. DFM & Material Consultation

Start with a signed NDA to protect your IP. We provide free Design for Manufacturability (DFM) analysis to optimize wall thickness and draft angles, plus expert advice on resin selection.

02. Rapid Prototyping

Validate your design before cutting steel. We offer Vacuum Casting, 3D printing and CNC machining to test form, fit, and function. We support Low-Volume Trial Runs for market verification.

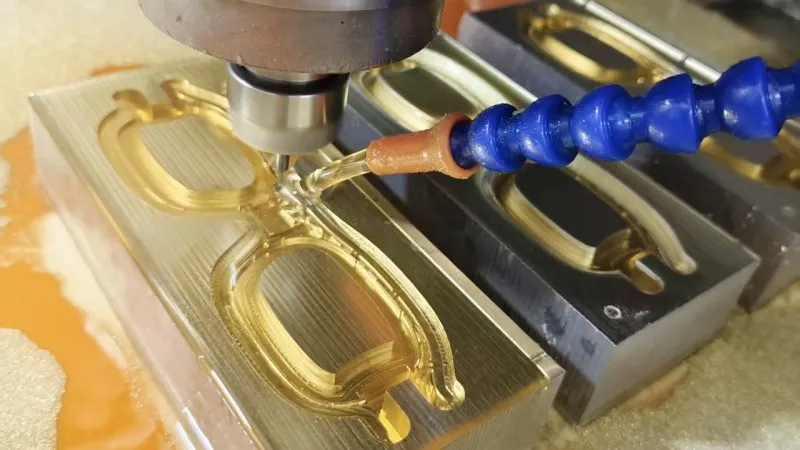

03. Precision Mold Making

In-house tooling powered by Makino & Mikron high-speed CNCs. We fabricate durable SPI Class 101-103 molds capable of μm-level accuracy and millions of shots.

04. Scientific Injection Molding

90T–1000T press capacity (Sumitomo/Fanuc). We utilize decoupled molding processes to ensure dimensional stability. ISO Class 7/8 Cleanroom available for medical parts.

05. Finishing & Assembly

A true one-stop solution. In-house Spray Painting, Silk Screening, Pad Printing, and Ultrasonic Welding. We handle full mechanical assembly to reduce your supply chain complexity.

06. Quality Assurance

Zero-defect commitment. We utilize CMM, RoHS 2.0 Testers, and Stress Testing equipment to verify every dimension. Full IPQC reports and Material Certifications (COA) provided with shipment.

Plastic Injection Molding Portfolio

Explore our diverse gallery of custom molded parts across six key industries. From high-precision medical devices to rugged industrial housings, filter below to see how we bring complex designs to life with our advanced molding capabilities.

Advantages of YG TeCH's Plastic Molding Services

01. Micron-level Precision Guarantee

- Mold processing accuracy reaches ±0.001 inches

- Handles 0.5mm holes, 0.3mm thin walls in one shot; burr-free edges

- Blue light scanning + 3D coordinate measurement

03. Flexible Project Support

- Free DFM analysis delivered within 48 hours of drawing submission

- 7-10 day prototype turnaround; 2-4 week lead time for simple molds

- Post-delivery process optimization suggestions provided

02. Compliant Quality Management

- ISO 9001 & ISO 13485 certified (annual audits maintained)

- Class 8 cleanroom for medical device component production

- Full batch traceability from raw materials to final inspection

04. Supply Chain Stability

- 10+ year partnerships with certified material suppliers

- RoHS/REACH testing for all incoming raw materials

- 30-day raw material inventory for common polymers

Plastic Injection Molding Solutions for Various Industries

Plastic injection molding is a go-to manufacturing choice for high-quality parts, offering clear advantages: it reduces costs, cuts component weight by up to 50%, minimizes waste, and enables the creation of complex, custom shapes.

Delivering mission-critical components for regulated sectors. From ISO 13485 medical devices to high-volume consumer electronics, we adapt our quality protocols to meet the specific standards of your industry.

Consumer Electronics

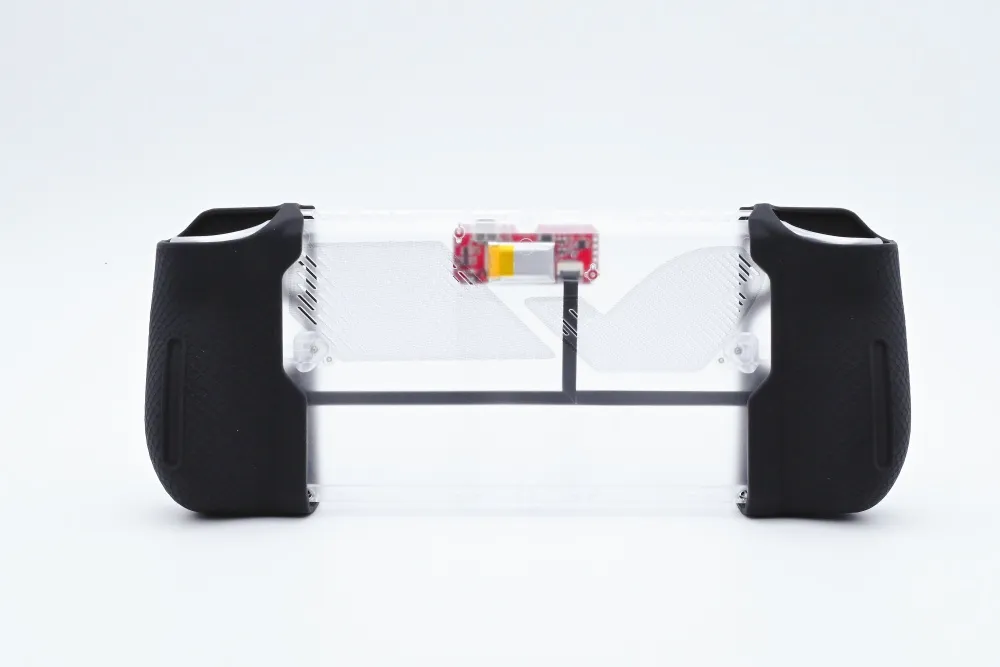

Enclosures for audio devices, wearables, and peripherals. Expertise in 2K molding and Insert Molding to integrate electronics seamlessly.

| Category | Components |

|---|---|

| Communication Devices | Phone Case, MacBook Cover, Tablet Case, Charger Housing |

| Wearable Tech | Watch Case, Smartwatch Bezel, Fitness Band Clasp, Earbud Charging Case |

| Audio-Visual Equipment | VR/AR Structural Parts, Speaker Grill Frame, Remote Control Buttons, Projector Lens Cover |

| Gaming Accessories | Game Controller Grip, Headset Ear Cushion Frame, Console Vent Grille, Charging Dock Base |

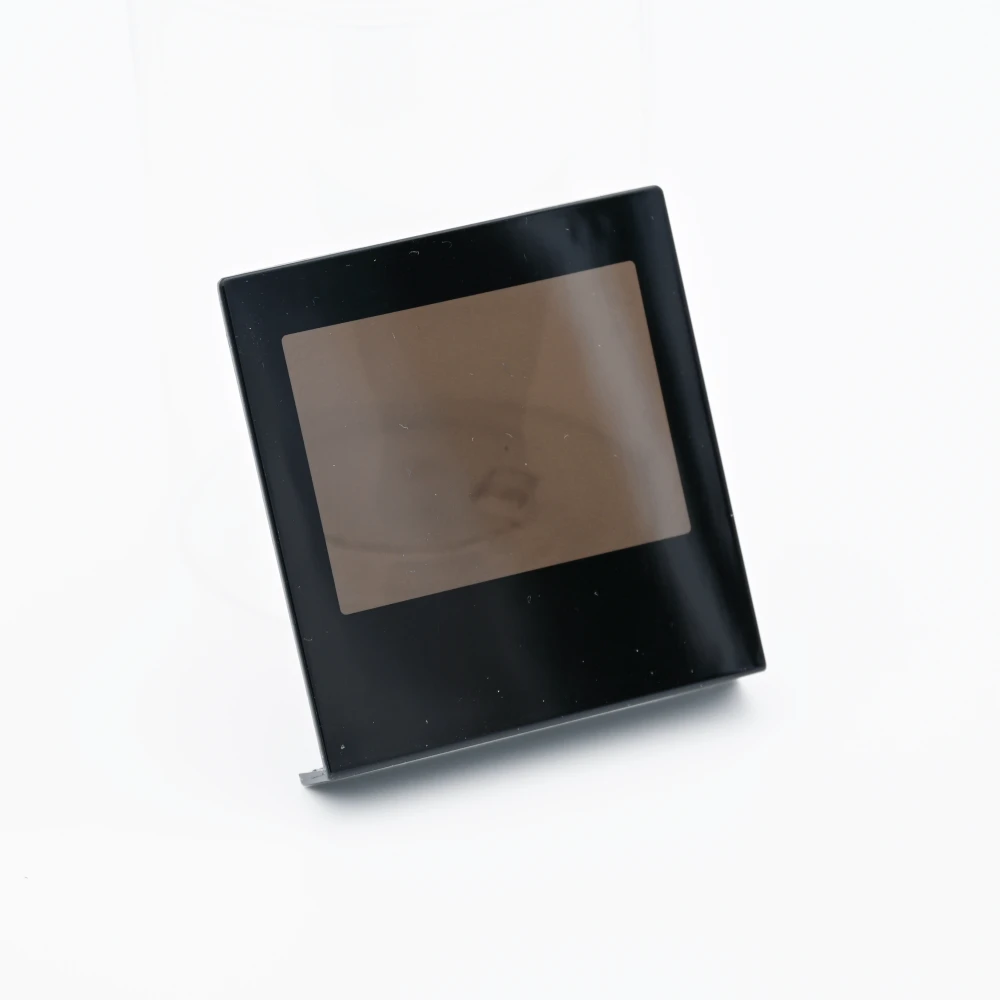

VR & AR & AI Glasses

Ultra-lightweight headsets and controller shells requiring thin-wall molding and premium surface finishing (Soft-touch painting, Laser etching).

| Category | Typical Components |

|---|---|

| Headset Structural Parts | Main Chassis, Front Faceplate, Heat Dissipation Vents, Battery Housing |

| Optical & Sensor Mounts | Lens Holder Rings, Pancake Lens Frames, Camera/Sensor Brackets, IPD Adjustment Mechanism |

| Controller & Interaction | Controller Grip Shells, IR Tracking Rings (Infrared Transparent), Trigger & Bumper Buttons, Haptic Feedback Housing |

| Wearable Ergonomics | Face Gasket Frames (Soft-touch), Headstrap Buckles, Audio Arm Housing, Nose Pad Bases |

Automotive

Precision interior parts, connectors, and under-the-hood components. Focus on high-heat resistance and structural integrity using PA66+GF and PPS. PPAP Level 3 documentation available.

| Category | Components |

|---|---|

| Interior Trim | Dashboard Panel, Door Armrest Trim, Center Console Knob Base, Seat Adjustment Button |

| Exterior Trim | Bumper Clip, Rearview Mirror Housing, Grille Accent, Window Seal Gasket Base |

| Functional Components | Wire Harness Clip, Oil Reservoir Cap, Brake Fluid Cup, Sensor Housing |

| Electronic System Parts | EV Charging Port Cover, Instrument Cluster Bezel, Steering Wheel Button Pad |

Medical & Healthcare

Medical-grade housings, surgical tool components, and micro-fluidic consumables. Produced in Class 7/8 Cleanrooms using biocompatible resins (PC, PP, PEEK).

| Category | Components |

|---|---|

| Diagnostic Equipment | Reagent Tube Rack, Sampling Cup, Testing Instrument Keypad, Cuvette Holder |

| Care Products | Infusion Pump Housing, Nebulizer Nozzle, Monitor Control Knob, Hemostat Handle Grip |

| Surgical Aids | Thermometer Shell, Blood Pressure Cuff Connector, Wheelchair Armrest Cover, Sterilization Case Latch |

| Therapeutic Devices | Trocar Sleeve, Surgical Tray Divider, Endoscope Handle Grip, Suture Pack Clip |

Industrial

Casings, gears, and brackets for power tools and instrumentation. Engineered for impact resistance and chemical durability.

| Category | Components |

|---|---|

| Power Tool Components | Drill Handle Grip, Grinder Guard, Sander Pad Frame, Impact Wrench Housing |

| Measuring Instruments | Caliper Housing, Level Vial Holder, Gauge Face Plate, Tester Probe Cover |

| Machinery Parts | Conveyor Roller Sleeve, Hydraulic Cylinder End Cap, Pneumatic Valve Knob, Gearbox Seal Cover |

| Workstation Accessories | Tool Cabinet Drawer Slide, Bench Vise Handle Grip, Tool Belt Clip, Parts Bin Divider |

Smart Home

Fire-retardant (V0) housings for smart switches, cameras, and sensors. High-gloss finishes with UV stability for long-term home use.

| Category | Components |

|---|---|

| Smart Controls | Smart Thermostat Housing, Voice Assistant Speaker Shell, Light Switch Panel, Remote Control Casing |

| Security Devices | Smart Doorbell Shell, Motion Sensor Cover, Camera Mount Bracket, Lock Keypad Frame |

| Environmental Regulation | Air Purifier Filter Frame, Humidifier Water Tank, Smart Valve Knob, Dehumidifier Control Panel |

| Cleaning Equipment | Robot Vacuum Shell, Dust Bin Assembly, Mop Attachment Frame, Filter Replacement Cover |

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

| Category | Components |

|---|---|

| Power Tool Components | Drill Handle Grip, Grinder Guard, Sander Pad Frame, Impact Wrench Housing |

| Measuring Instruments | Caliper Housing, Level Vial Holder, Gauge Face Plate, Tester Probe Cover |

| Machinery Parts | Conveyor Roller Sleeve, Hydraulic Cylinder End Cap, Pneumatic Valve Knob, Gearbox Seal Cover |

| Workstation Accessories | Tool Cabinet Drawer Slide, Bench Vise Handle Grip, Tool Belt Clip, Parts Bin Divider |

Plastic Injection Molding Cases

View examples of YG’s injection molding projects—covering material selection, molding processes to mass production for different industries.

Thanks for Their Trust

Tom L.

“My colleagues from large CE brands highly recommended YG. In our startup project, YG acted as a true partner, not "just a vendor." The well-managed team has a long-term vision, excellent communication, and quickly resolves issues. They're smart, professional, and fun. I'm deeply grateful to work with them.”

“We have established business relationship with YuanGuan since 5 years ago. No matter or order is big or small, we have always felt their exquisite, considerate service and got their best assistance every time. In our entire product supply chain, YuanGuan is one of our strategic partners in China. Here, we strongly recommend this company to all friends in the industry.”

Jimmy G.

Andy L.

“Slimcase has worked with YG on multiple important phone case projects. We are happy with the product quality because of the high-skilled engineers and up-to-date machinery. Moreover, support from the team is outstanding. YG is becoming our strategic development partner in China.”

We Precisely Tailor Your IInjection Molding Needs

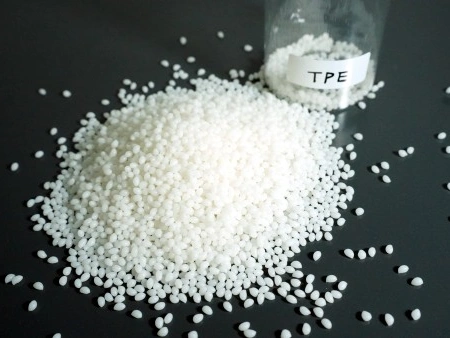

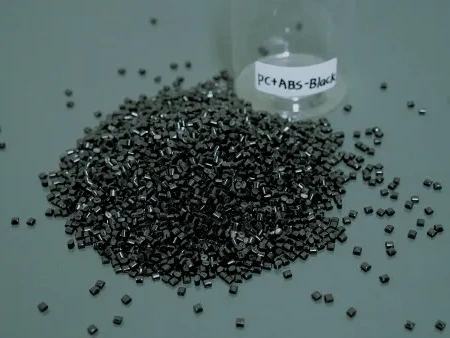

Plastic Injection Molding Materials

YG offers a wide range of available injection molding materials, covering core categories such as general materials, engineering materials, specialty engineering plastics, and modified reinforced plastics.

We can precisely match materials to customer needs and support procurement from customer-specified suppliers to ensure optimal compatibility between materials and injection molded parts.

PC

PP

TPU

TPE

TPE-80 Shore A

POM

ABS

PC+ABS

PA6+15%GF

PCTG TX1501HF

Plastic Injection Molding Post-Processing Services

Post-injection molding post-processing is crucial for achieving the ultimate performance and appearance of plastic parts. It optimizes surface texture, enhances durability, and meets industry compliance requirements.

YG offers post-processing services such as painting, pad printing, antimicrobial treatment, CNC precision machining, and wear-resistant/UV-resistant coatings to meet the plastic part needs of various industries.

| Category | Specific Process | Key Features | Industry Standards |

|---|---|---|---|

| Appearance Enhancement | Spray Coating (Painting) UV / PU / Soft-Touch | Custom color matching (Pantone/RAL) Excellent surface texture control | Refer to: IATF 16949 Compliance: RoHS 2.0 |

| Pad & Screen Printing Logo & Marking | Multi-color printing supported High precision alignment | Medical: ISO 10993-1 Food Contact: FDA | |

| Plastic Plating Chrome / NCVM | Metallic look for plastic parts Stable adhesion performance | Test: ASTM D3359 EU RoHS 2.0 Compliant | |

| Performance Enhancement | Hard Coating Protective Finish | Enhanced scratch resistance Protects against daily wear | Hardness Test: ASTM D3363 Abrasion: ASTM D4060 |

| UV-Resistant Coating Outdoor Protection | Prevents yellowing and fading Weatherability tested | Test Std: ASTM G154 | |

| Dispensing & Sealing Waterproofing | Gasket dispensing for sealing Dust & moisture protection | Rating: IEC 60529 (IPXX) UL 50E Compliant | |

| Structural Finishing | CNC Precision Machining Secondary Operations | Drilling, tapping, and facing High Precision: ±0.01mm | Aerospace: AS9100 Medical: ISO 13485 |

| Deburring & Polishing Surface Refinement | Removes flash and sharp edges Smooth surface finish | Cleanliness: ISO 16232 Biocompatibility: ISO 10993 | |

| Insert Installation Heat Staking | Secure metal-to-plastic bonding High pull-out force | Automotive: IATF 16949 Quality: ISO 9001 |

Polishing

Pad Printing

Heat Treatment