Consumer Electronics Solution

Industry Overview

The consumer electronics industry is at the forefront of technological innovation, driving the development of new and exciting products that shape how we live and connect. With rapid advancements and ever-changing consumer preferences, companies must innovate swiftly to stay competitive. This dynamic environment demands agile and reliable prototyping solutions that can keep pace with industry trends like smart technology integration and sustainable design.

Industry Challenges

Consumer electronics companies face several key challenges

These challenges require a partner who can provide fast, flexible, and high-quality prototyping and manufacturing services.

Short Product Lifecycles

The need to quickly bring new products to market and update existing ones.

High Consumer Expectations

Delivering products that meet high standards of quality, functionality, and design.

Global Competition

Standing out in a crowded market with unique and innovative offerings.

Services we provide

YG offers a comprehensive range of services tailored to the consumer electronics industry

Product Design

Our expert designers work with you to create innovative and functional product designs.

Prototype Manufacturing

Develop precise prototypes quickly to test and refine your ideas.

Injection Molding Production

Efficiently produce high-quality parts with our advanced injection molding capabilities.

Product Assembly

Seamlessly integrate components into fully assembled products.

Quality Control

Ensure your products meet the highest standards with our rigorous quality assurance processes.

Shipping

Dependable logistics support to deliver your products on time, anywhere in the world.

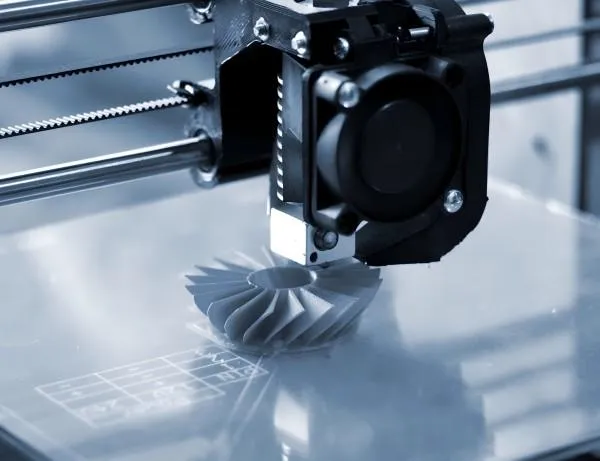

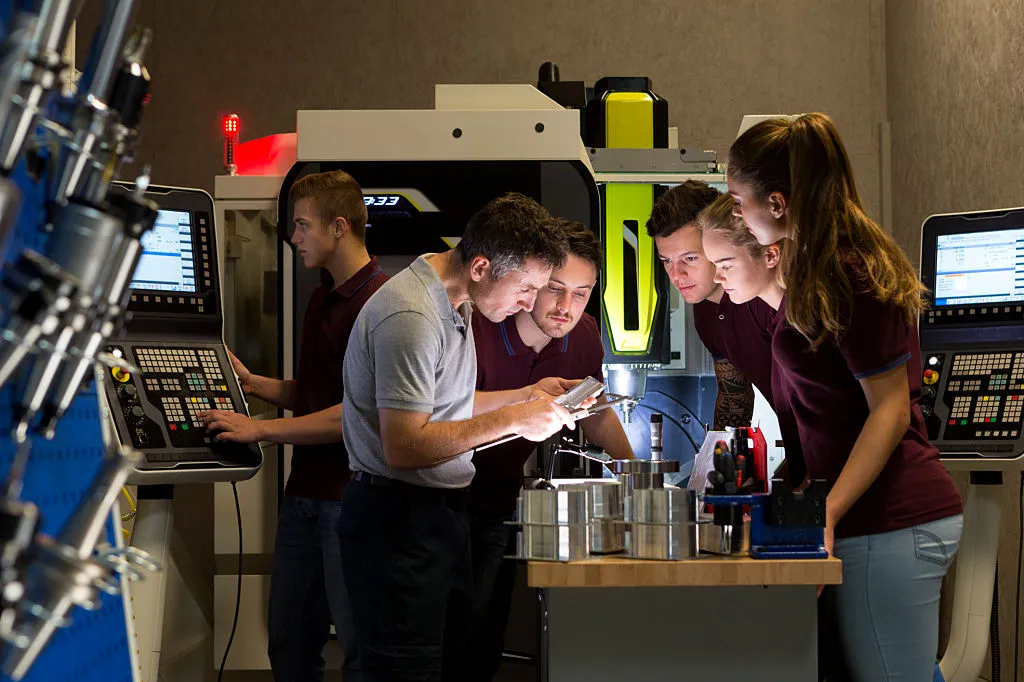

Our Manufacturing Capabilities

Utilizing state-of-the-art technology, YG excels in delivering precise and efficient manufacturing solutions. Our capabilities include CNC machining, 3D printing, and automated assembly, ensuring that your prototypes and products are manufactured to the highest quality standards. Our experienced team is dedicated to supporting your project from concept to completion.

Why Choose YG as Your Partner

Choosing YG for your Medical device projects means partnering with a team that understands the industry’s demands and delivers results.

Comprehensive Solutions

From initial design to final delivery, our one-stop service streamlines your project workflow.

Proven Expertise

A track record of delivering high-quality prototypes and products on time and within budget.

Startup-Friendly Approach

We offer flexible solutions and competitive pricing to support new and emerging companies.

Customer-Centric Service

We provide personalized attention and responsive support to meet your specific needs.

Consumer electronics showcase

We focus on the design and manufacture of consumer electronics, providing our customers with one-stop service from concept to finished product. Through successful cases such as mobile workstations and mechanical keyboards, we have demonstrated outstanding innovative design and precision manufacturing capabilities. We are guided by customer needs to ensure high-quality delivery of each project, winning market recognition and customer trust.

Ready to innovate in the consumer electronics space? Contact us today to learn how YG can help you bring your ideas to life with precision and speed.