Choosing the Right Prototyping Method for Your Business Needs

Selecting the appropriate prototyping method is crucial for achieving your project goals effectively and efficiently. Each prototyping technique offers unique advantages and considerations.

Advantages:

1. Precision: Ideal for accurate, detailed prototypes with tight tolerances.

2. Material Versatility: Supports various materials, suitable for diverse applications.

3. Durability: Produces robust prototypes for rigorous testing.

Considerations:

1. Cost: Higher setup costs make it less economical for small batches.

2. Lead Time: Slower than 3D printing for simple designs.

Advantages:

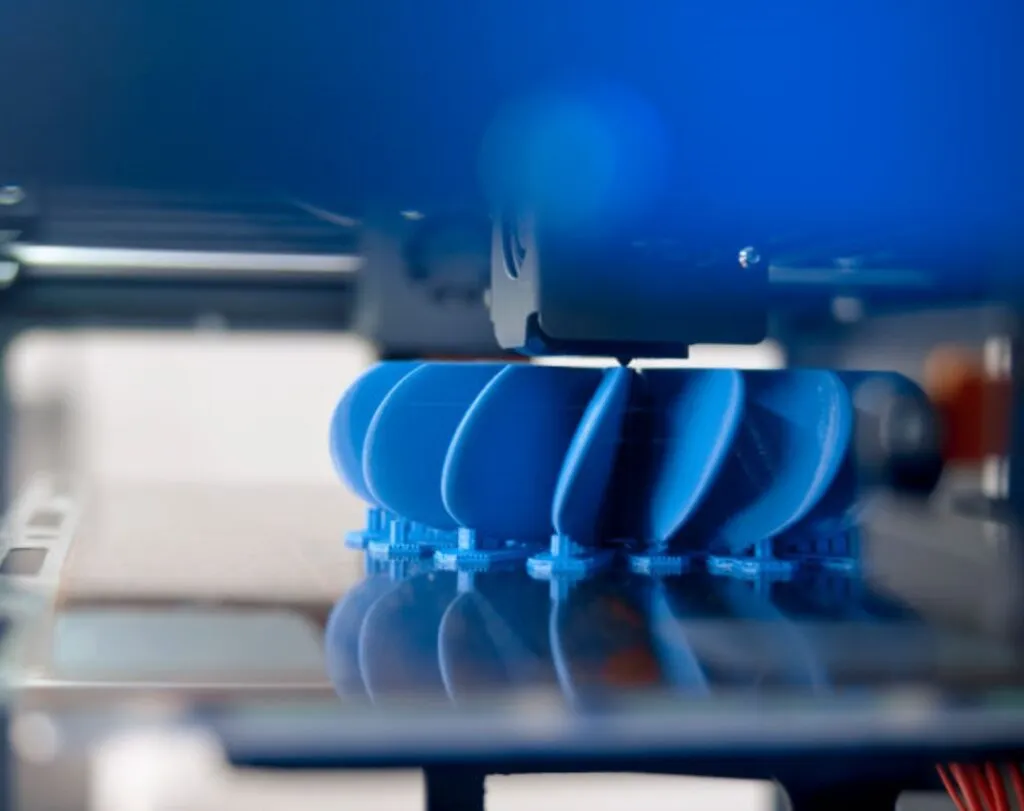

1. Speed: Rapid production for quick design iterations.

2. Complex Geometry: Handles intricate shapes with ease.

3. Cost-Effective: Ideal for low-volume and one-off prototypes.

Considerations:

1. Material Limitations: Fewer material options compared to CNC.

2. Surface Finish: May need post-processing for smoothness.

Advantages:

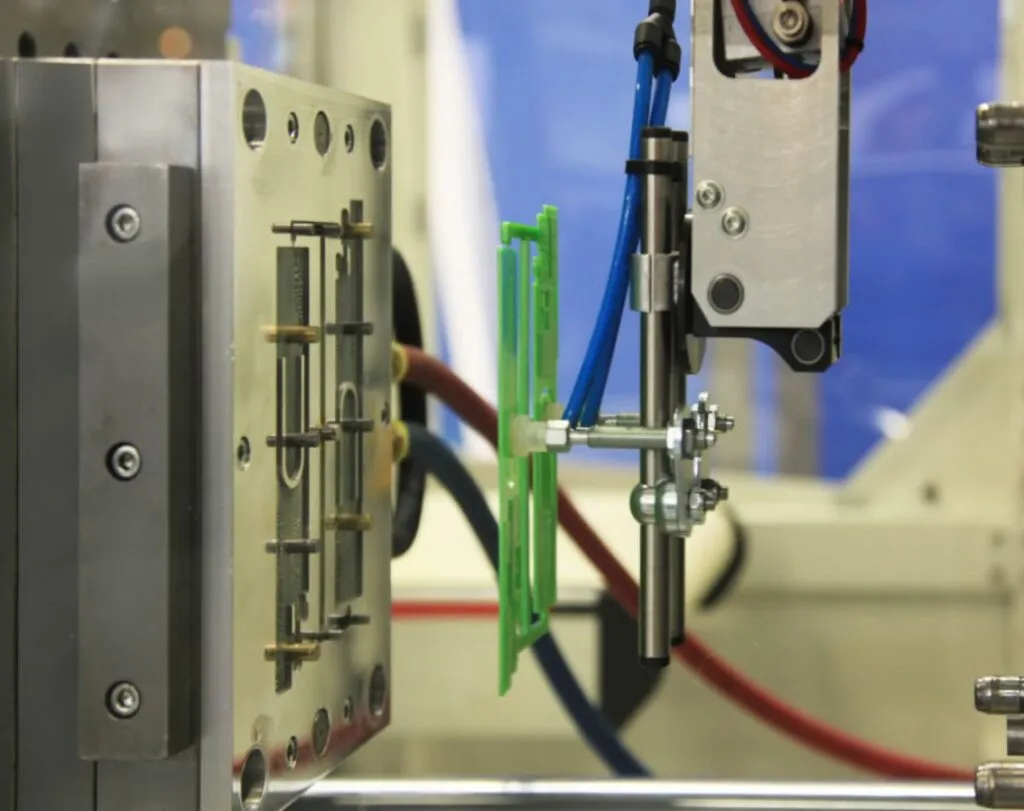

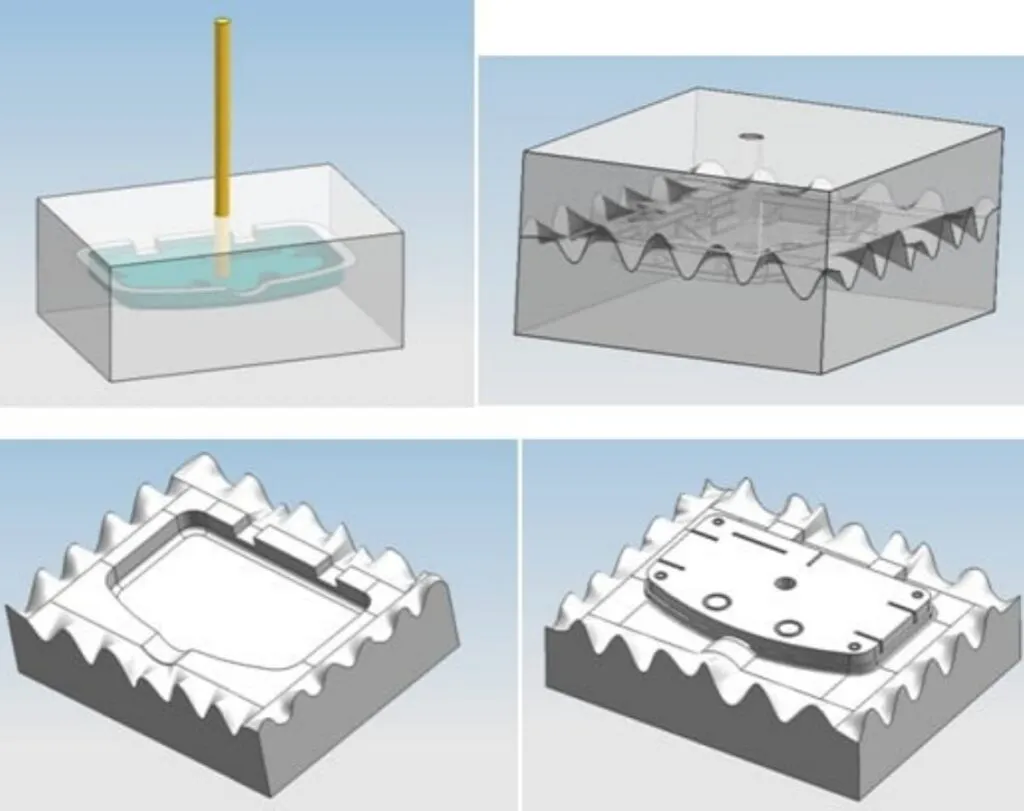

1. Production-Quality: Prototypes closely mimic final products.

2. Scalability: Smooth transition from prototype to production.

3. Consistency: Uniformity in multiple prototypes.

Considerations:

1. Setup Cost: Higher initial costs due to mold creation.

2. Lead Time: Longer than 3D printing for complex designs.

Advantages:

1. Surface Finish: High-quality finishes ideal for testing.

2. Material Variety: Simulates different production scenarios.

3. Cost-Effective: Suitable for small batch production.

Considerations:

1. Durability: Less durable than CNC or injection molding.

2. Lead Time: Longer than 3D printing but offers better finishes.