Rapid Tooling Making

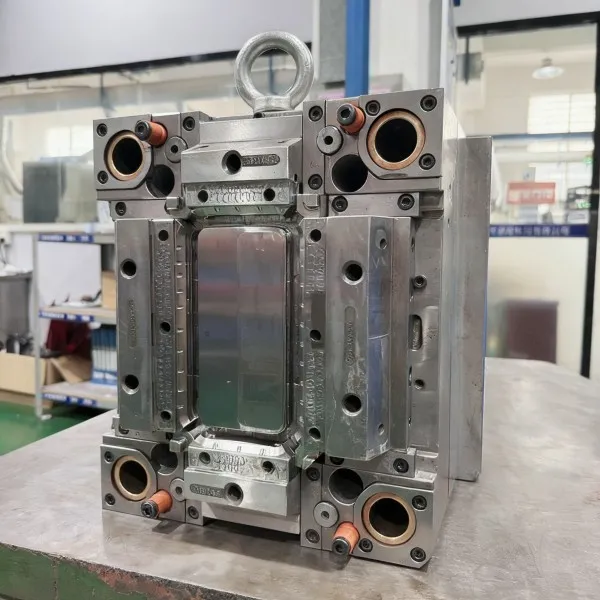

Rapid tooling is the best choice to help you quickly verify prototypes and launch products. It works in seamless sync with subsequent rapid injection molding, turning your mold concepts into physical parts quickly.

We will introduce you to the cost, time, materials, market feedback, precautions, etc. of parts made using YG’s rapid tooling.

What is Rapid Tooling?

Rapid Tooling is the strategic bridge that connects your “design prototype” to “full-scale production.”

Unlike traditional production tooling, which is built for maximum longevity and the lowest per-part cost, the core advantages of Rapid Tooling are speed and agility. It is specifically designed to quickly produce small batches of high-quality, production-grade parts, enabling you to:

√ Validate your design and conduct functional testing.

√ Gauge market response and gather user feedback.

√ Fulfill crowdfunding campaigns, pre-orders, or early-stage sales.

In essence, while 3D printing is ideal for a handful of visual prototypes, and mass production tooling is for millions of parts, Rapid Tooling is the smart, cost-effective choice for getting real, functional products in hand and accelerating your time to market.

Challenges & Solutions

We understand the real challenges in bringing a new product to market:

Challenge 1

High upfront cost and risk of traditional tooling for an unproven design.

Challenge 2

Long lead times that delay your entire project.

Challenge 3

The need for real, functional parts for market testing or sales.

Here’s how we solve them.

Integrated Development for Higher Success

For the most efficient path, we handle both the rapid tooling and the injection molding. By aligning mold design with production from the start, we prevent costly missteps and typically achieve over 30% higher product yield.

A Faster, More Focused Process

Our in-house capabilities—including 5-axis CNC and EDM equipment—allow us to deliver robust rapid tools in weeks, not months.

Production-Ready Parts from Day One

We use the same engineering-grade materials and quality controls as our full-scale production. The parts you receive are functional, market-ready, and built to your specifications.

Rapid Tooling Technology & Capabilities

How do we guarantee faster time-to-market and lower risk? It starts with our technical capabilities. Our in-house control over precision machining and injection molding allows us to align every aspect of the process, delivering rapid tooling solutions that are built for performance, not just prototypes.

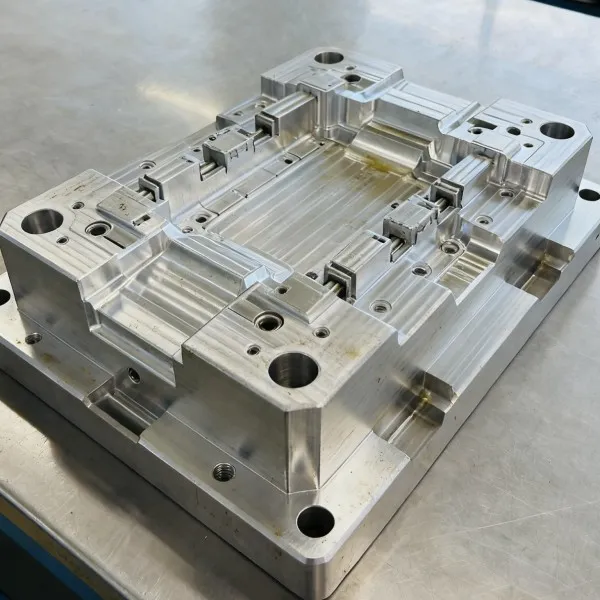

01. Precision Machining & Equipment

- 5-Axis CNC for Complex Geometries

- EDM for Intricate Details

- In-House Toolroom Control

02. Engineering & Process Excellence

- Collaborative DFM Analysis

- Optimized for Injection Molding

- Seamless Handoff to Production

03. Quality & Repeatability

- Mold Life: 50,000+ Shots

- Tight Tolerances (±0.005 mm)

- Production-Grade Materials

04. Speed & Project Management

- 10-15 Day Standard Lead Time

- Dedicated Project Engineer

- Real-Time Progress Updates

Rapid Tooling Vs. Production Tooling: Making the Right Choice

Every project has unique needs. Understanding the fundamental differences between rapid and production tooling is key to selecting the most cost-effective and efficient path for your product development. The choice depends on your stage in the product lifecycle.

Still Unsure Which Path is Right for You?

A good rule of thumb is to start with Rapid Tooling when:

- Your design may still evolve.

- You need to validate the market.

- Your initial volume requirement is under 10,000 units.

It serves as a low-risk strategy to de-risk your full-scale production investment. When your demand is confirmed and volumes are high, Production Tooling becomes the most economical choice.

Our engineers can help you analyze your project’s specific requirements and recommend the optimal approach.