Tom L.

from Tempest Clock

Your Reliable Mold Making Partner in China. High-quality molds, fair pricing, and clear English communication. We ensure your project runs smoothly from design to delivery.

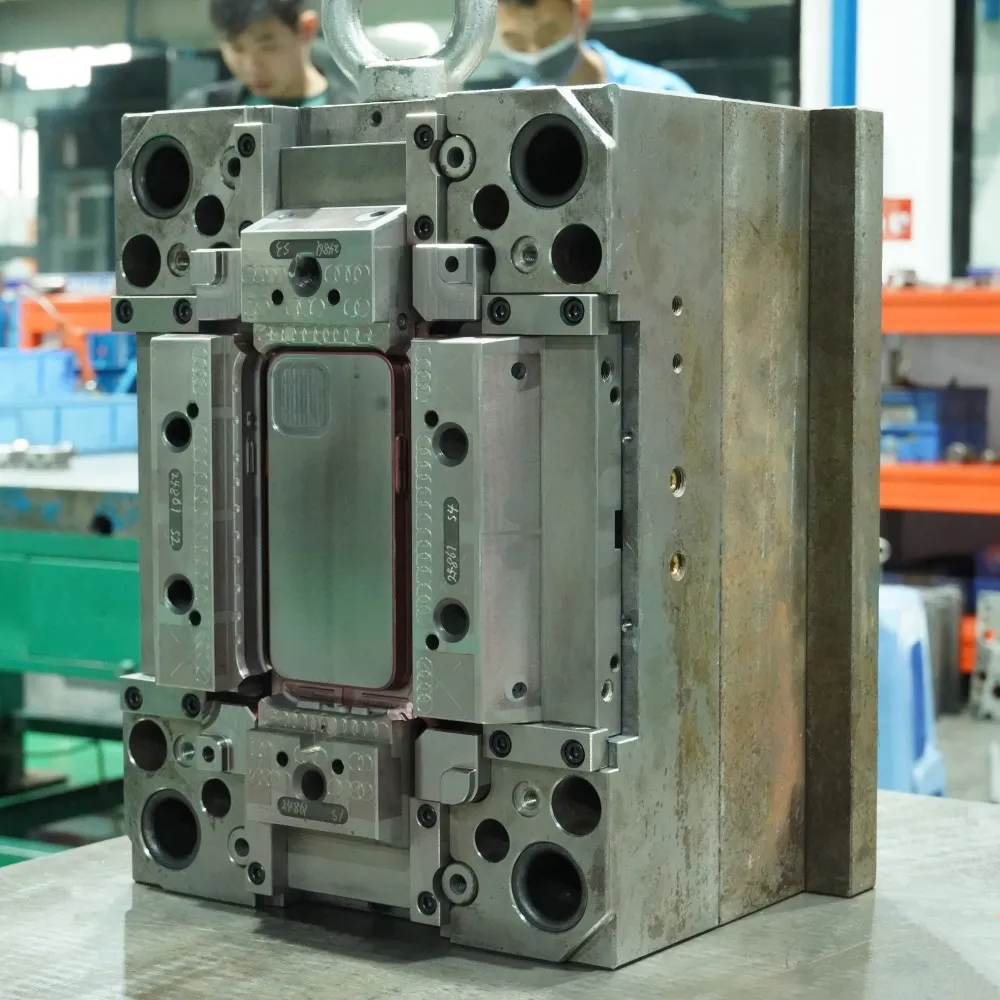

Injection Mold Manufacturing is a specialized process for creating precision metal molds. Using these customized “steel stamps,” your plastic products (such as phone cases, medical parts, or automotive components) can be mass-produced on injection molding machines at high speed, low cost, and with zero error.

Why should you care about injection mold manufacturing? A high-quality injection mold can produce over one million parts at a cost as low as $0.02 per piece (at mass production), significantly lower than 3D printing or CNC machining. In essence, investing in superior injection mold manufacturing builds a reliable, scalable foundation for your product’s mass production success.

Founder/CEO

Founder/CTO

Marketing Director

Finance Officer

Mold Fabrication Solutions

Leveraging advanced Sumitomo & Fanuc machines and ISO 13485 processes. We turn your complex concepts into precision reality with zero compromise on quality.

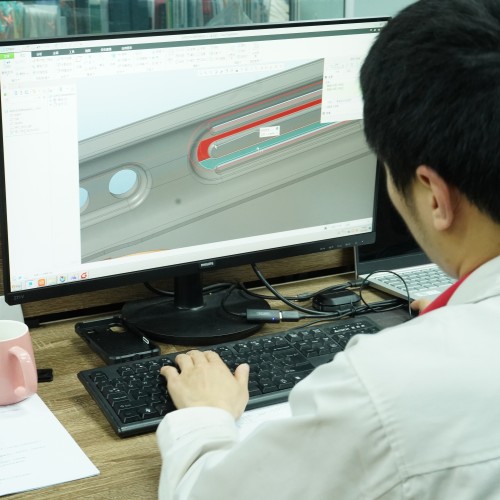

Full 3D/2D design using UG & MoldFlow. We engineer efficient cooling systems and optimal gating to reduce cycle time and ensure defect-free molding. Free DFM included.

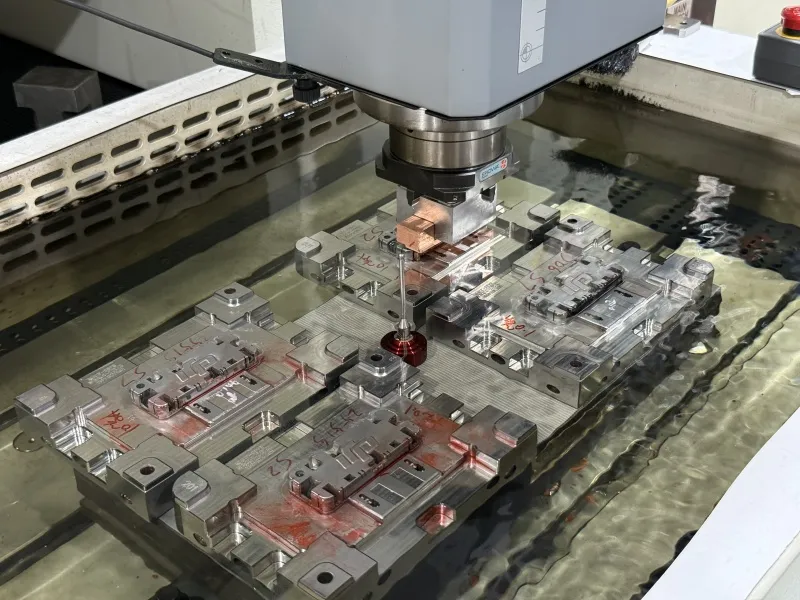

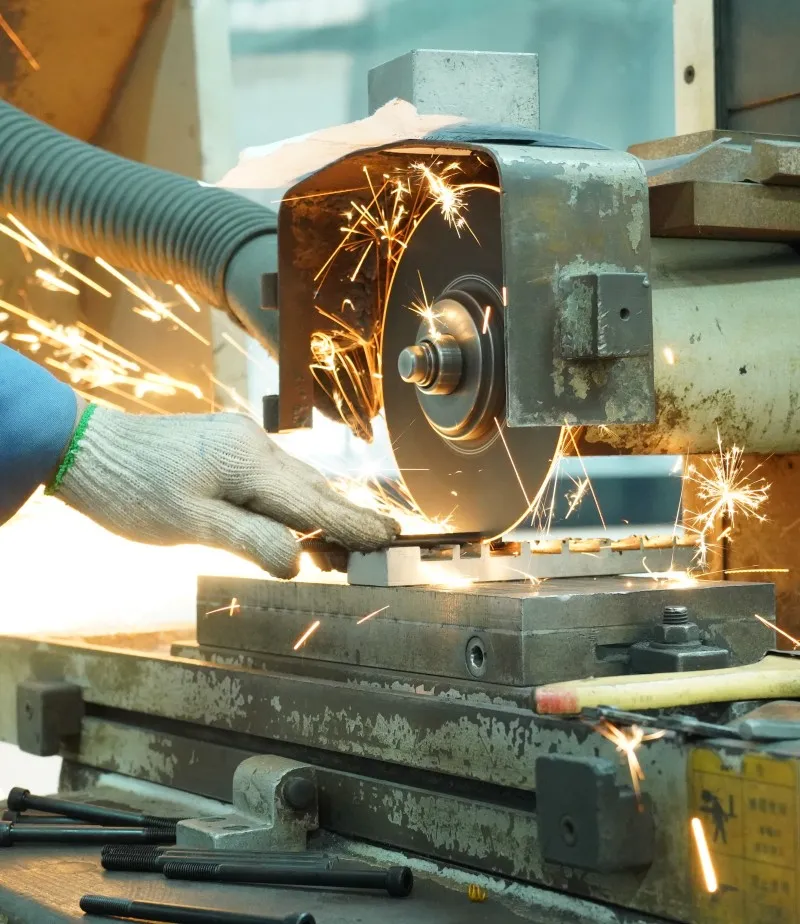

Equipped with high-speed Makino/Fanuc CNCs and Mirror EDM. We achieve tight tolerances of +/- 0.005mm for complex connectors, gears, and optical lenses.

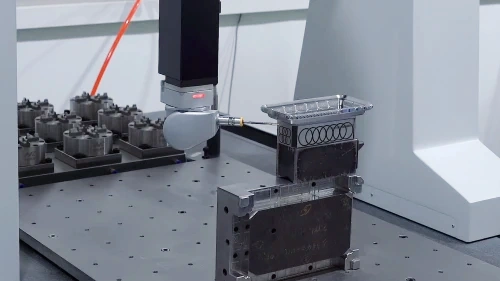

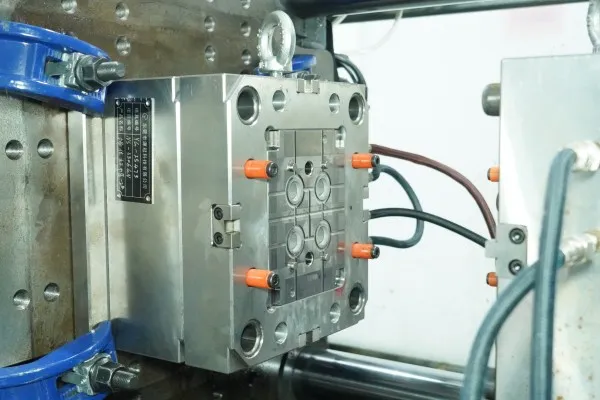

Verified by CMM, Projectors, and RoHS testers. We strictly follow ISO 13485 & ISO 9001 protocols to ensure every dimension meets your drawing.

Scale from trial runs to millions. Equipped with 120T-800T Fanuc & Sumitomo machines running 24/7 to guarantee stable quality and on-time delivery.

Creating an injection mold involves a structured process to ensure precision and reliability. Here’s how it typically works:

Our team at YG starts by reviewing your product design (3D/2D drawings or samples). We check details like wall thickness, undercuts, and material needs to confirm if injection molding is suitable. If design tweaks would make manufacturing smoother, we’ll discuss adjustments with you.

Using tools like SolidWorks or UG, YG’s engineers design the full mold structure—including parting lines, gating systems, cooling channels, and ejection mechanisms. We also select mold materials (e.g., S136, 718H) based on your product’s needs and source them promptly.

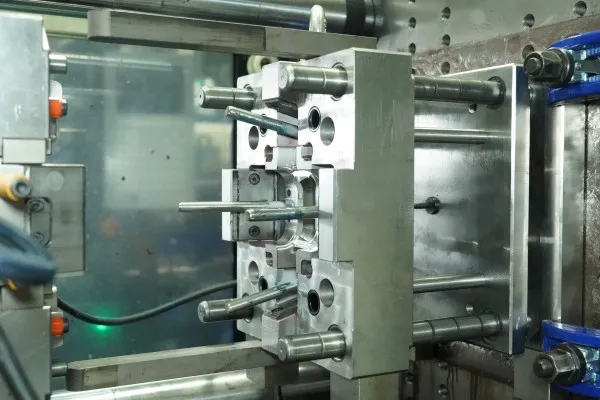

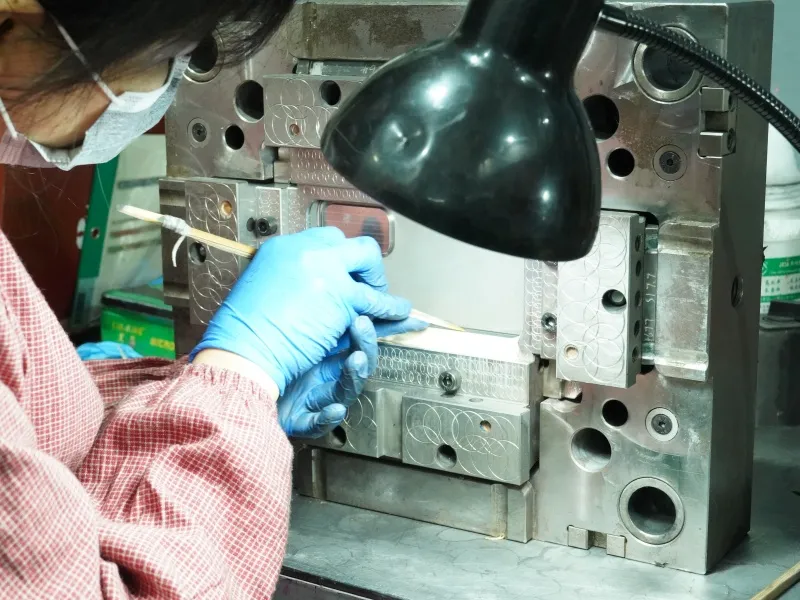

All mold parts are machined at YG with strict precision: Rough shaping to remove excess material. Heat treatment to harden steel. Fine machining (via CNC, EDM, grinding) for exact dimensions and surface quality. Final polishing for smooth finishes.

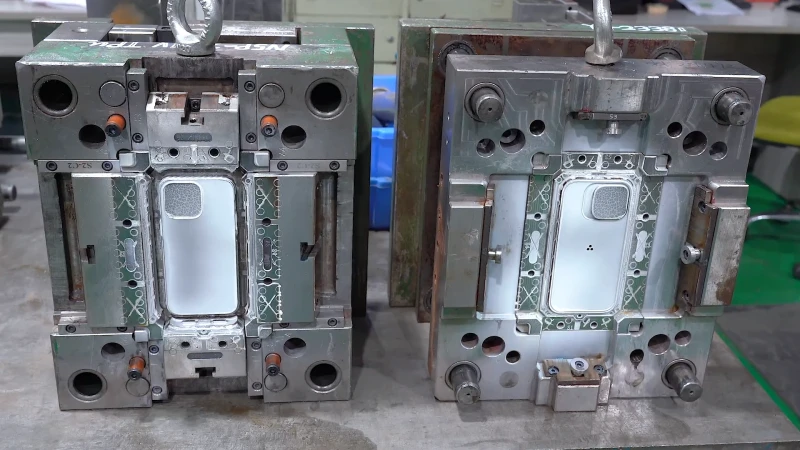

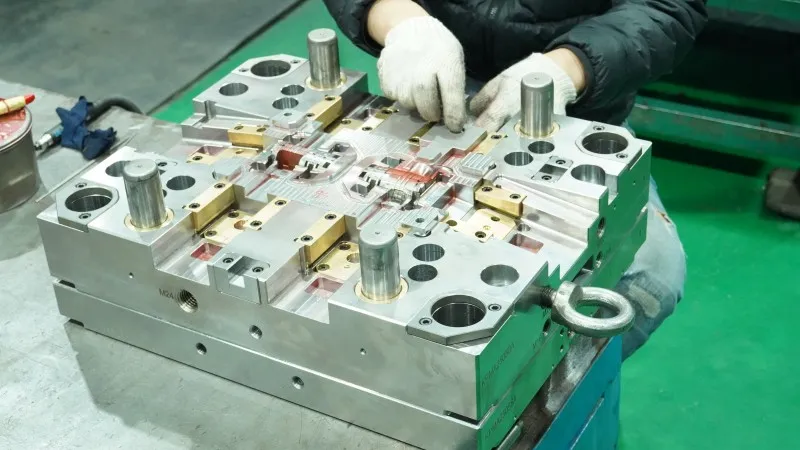

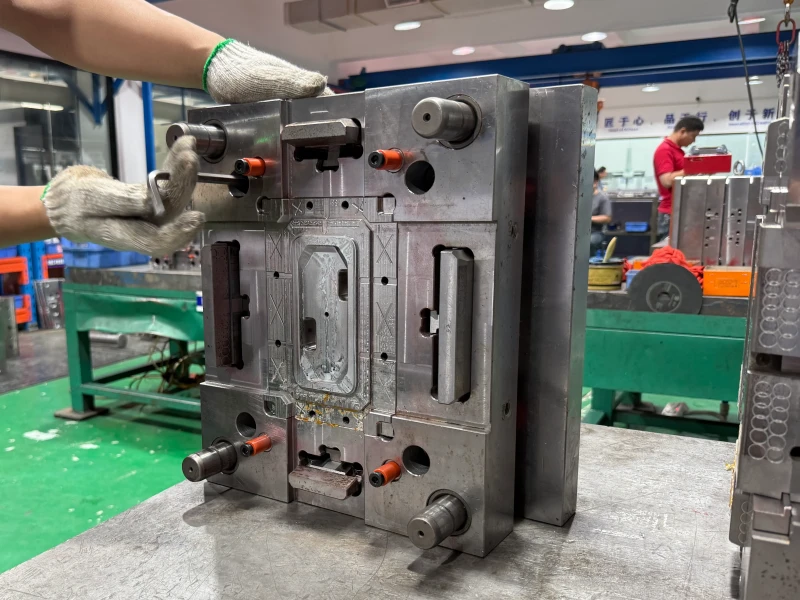

Our technicians assemble all machined parts into a complete mold. We ensure tight fits: guide pins slide smoothly, ejection systems work without jamming, and mold halves seal properly to prevent excess plastic (flash).

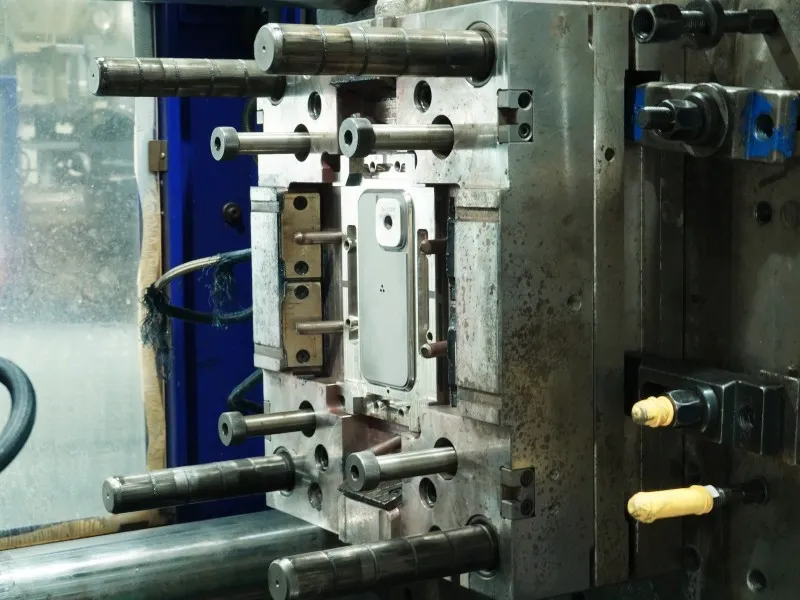

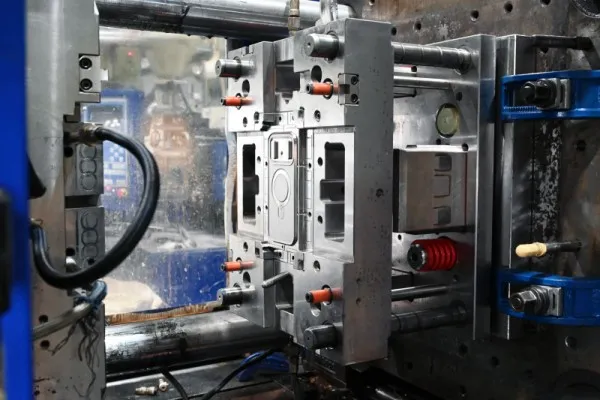

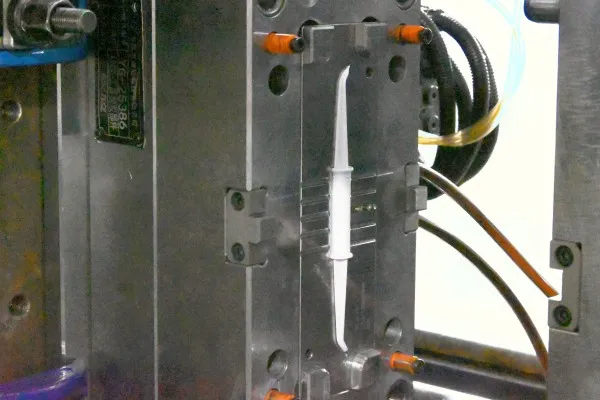

The mold is tested on our injection machines: Initial trials (T1, T2) to check for defects like incomplete filling or warping. Adjustments to the mold or processing settings and small-batch tests until parts match your standards.

Once the mold passes all tests, YG proceeds to large-scale production. We provide you with inspection reports and maintenance guidelines to support long-term use of the mold.

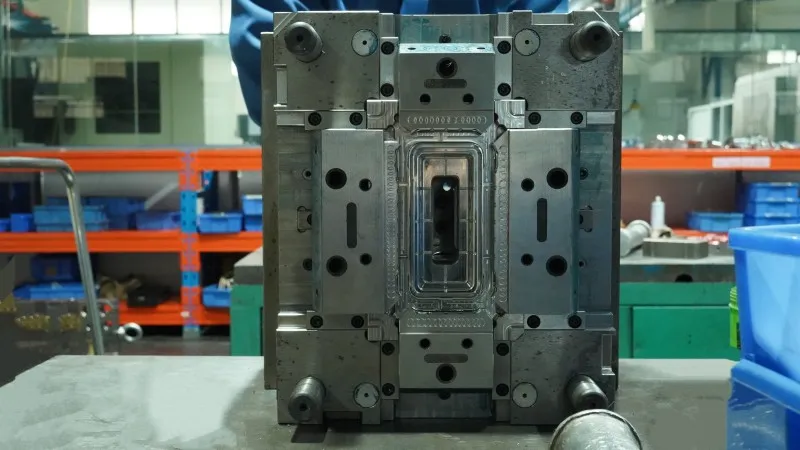

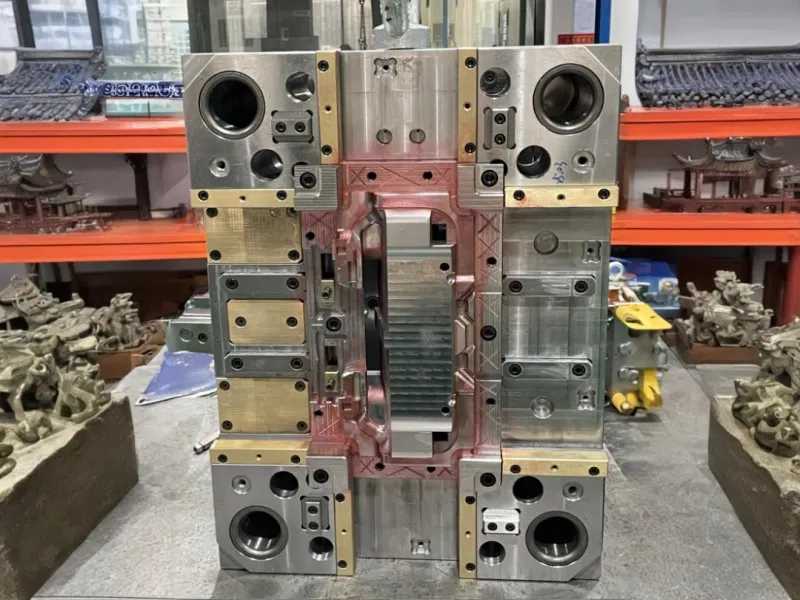

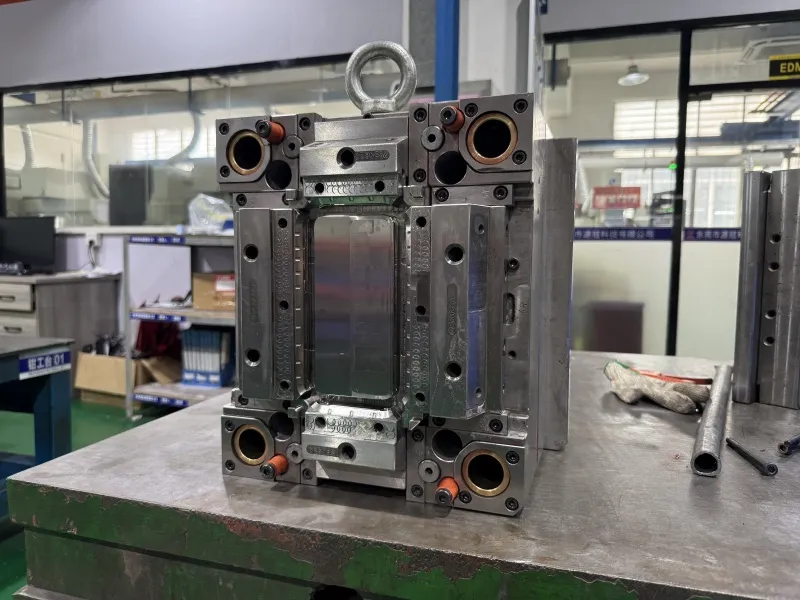

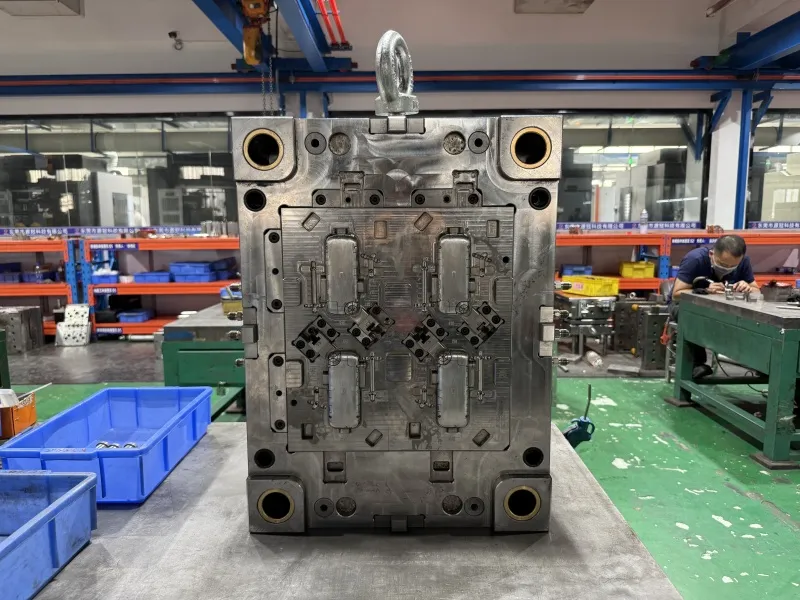

A selection of our recent tooling projects. From multi-cavity precision molds to large automotive tools, demonstrating our machining quality and structural durability.

The ultimate goal of mold manufacturing services is to produce plastic parts that satisfy you. These results are reflected in practical applications across various industries.

The following are applications of YG injection molds in consumer electronics, automotive interior parts, medical devices, smart home products, and industrial tools, and other fields.

Phone Cases

Medical Device Parts

Medical Device Parts

Automotive Interior Parts

Precision, consistency, and aesthetics directly impact product success. YG leverages advanced injection mold manufacturing technologies to address the specific challenges of producing miniature, complex, and high-quality components.

Multi-axis CNC machines process a variety of complex mold parts through high-speed milling, turning, drilling, and precision grinding.

Complex cavities and shapes can be created in hard metals by eroding the material using a controlled electrical discharge between the electrode and the workpiece.

Features a thin metal wire as the electrode, which moves along a programmed path to cut through the workpiece via electrical discharges.

Involves processes like polishing, buffing, and chemical treatment to refine the mold surface, this improves product release and extends mold service life.

Real Factory. Real People.

Our in-house mold shop is equipped with high-speed CNCs, Mirror EDMs, and Wire Cuts. But our true asset is our team: veteran mold makers with 10+ years of experience who ensure every core and cavity meets your exact specifications.

We guarantee the mold life based on the steel grade you choose.

Class 101 (Hardened Steel): Guaranteed for 1,000,000+ shots.

Standard (P20/718): Guaranteed for 300,000 – 500,000 shots.

If the mold stays at YG TeCH for production, we offer free lifetime maintenance.

If the dimensions do not match your drawings due to our error, we will modify the mold for free until it is correct. If the issue stems from your design change, we only charge the modification cost—no profit added.

Transparency is key. We send a Weekly Progress Report every Monday, including photos and videos of the machining process (CNC, EDM). You will know exactly what stage your mold is in.

Yes. We build Export-Ready Molds strictly following international standards. We use universal standard components (gate locators, cooling fittings) to ensure your tooling is compatible with standard injection machines globally.

You own 100% of the mold. Once you have paid for the tooling, it is your asset. If you decide to move production or export the mold later, we will package it and assist with shipping immediately. No penalties.

Typically, we provide 10-20 shots of free samples (parts) immediately after the T1 trial. We will ship these samples to you via DHL/FedEx for your approval before mass production begins.

Yes. For low volumes, we recommend Rapid Tooling using softer aluminum or P20/718 steel. This reduces tooling costs by 30-50% and delivers parts much faster than traditional production molds.