In today’s highly competitive manufacturing industry, responding quickly to market demand is one of the keys to business success. Rapid Tooling, as an innovative technology, is changing the way products are developed and produced. This article will delve into the definition, application, technical details of Rapid Tooling, and its advantages in various industries.

1. What is Rapid Tooling?

Rapid Tooling refers to the process of using rapid manufacturing technology to produce molds or mold inserts. Compared with traditional mold manufacturing, Rapid Tooling significantly shortens production time and reduces costs. By using 3D printing and other advanced technologies, companies can manufacture molds for small batch production or functional testing in a short time.

2. Technical details of Rapid Tooling

Rapid Tooling refers to the process of using rapid manufacturing technology to produce molds or mold inserts. Compared with traditional mold manufacturing, Rapid Tooling significantly shortens production time and reduces costs. By using 3D printing and other advanced technologies, companies can manufacture molds for small batch production or functional testing in a short time.

3D printing: 3D printing technology allows manufacturers to create complex geometries that are difficult to achieve in traditional mold manufacturing. It can be used to manufacture mold inserts or entire molds. For example, in the medical device industry, 3D printing technology is used to make complex mold inserts to produce syringes with fine channels. This design is almost impossible to achieve in traditional mold manufacturing.

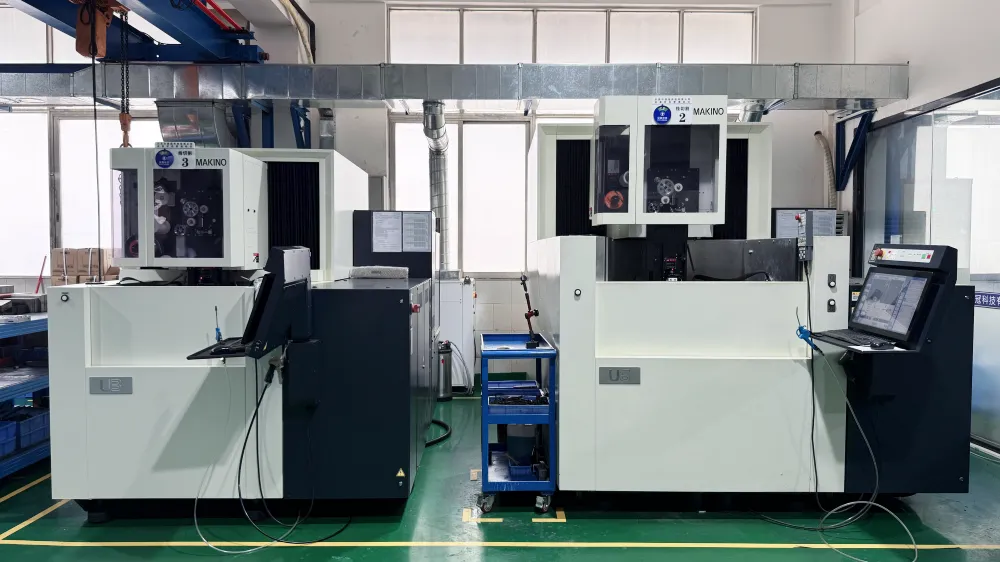

CNC machining: CNC (computer numerical control) machining is a high-precision manufacturing technology suitable for making metal molds or mold parts. It can quickly process complex shapes and has a wide range of material options. Airlines use CNC machining technology to make molds for aircraft parts, ensuring the accuracy and durability of each part.

Injection molding: In the technical details of Rapid Tooling, the injection molding process is one of the key methods to achieve rapid production and flexible manufacturing. By combining rapid manufacturing technology, the injection molding process can significantly improve production efficiency, especially when rapid iteration and small batch production are required. For example, a toy company needs to quickly launch a limited edition toy for the holiday. Through Rapid Tooling injection molding technology, they are able to complete mold making and products within a few weeks

Casting: In some cases, Rapid Tooling technology can be combined with rapid casting or injection molding processes to achieve higher production efficiency. For example, consumer electronics companies use rapid casting technology to produce molds for mobile phone shells for rapid market testing.

3. Application Cases of Rapid Tooling

Rapid Tooling plays an important role in multiple industries:

Automotive Industry: In automobile manufacturing, Rapid Tooling is used to produce prototypes and small batches of parts, such as dashboards and interior parts. This approach allows for rapid iteration of designs and functional verification before mass production. For example, an automobile manufacturer used Rapid Tooling to quickly produce a prototype dashboard of a new model to display and collect feedback at an auto show.

Aerospace: The aerospace industry uses Rapid Tooling to produce complex components and structural parts. By rapidly manufacturing molds, companies are able to shorten development cycles and increase the market response speed of new products. For example, airlines use Rapid Tooling to manufacture prototype molds for cabin interiors, allowing rapid adjustments in design to improve passenger comfort.

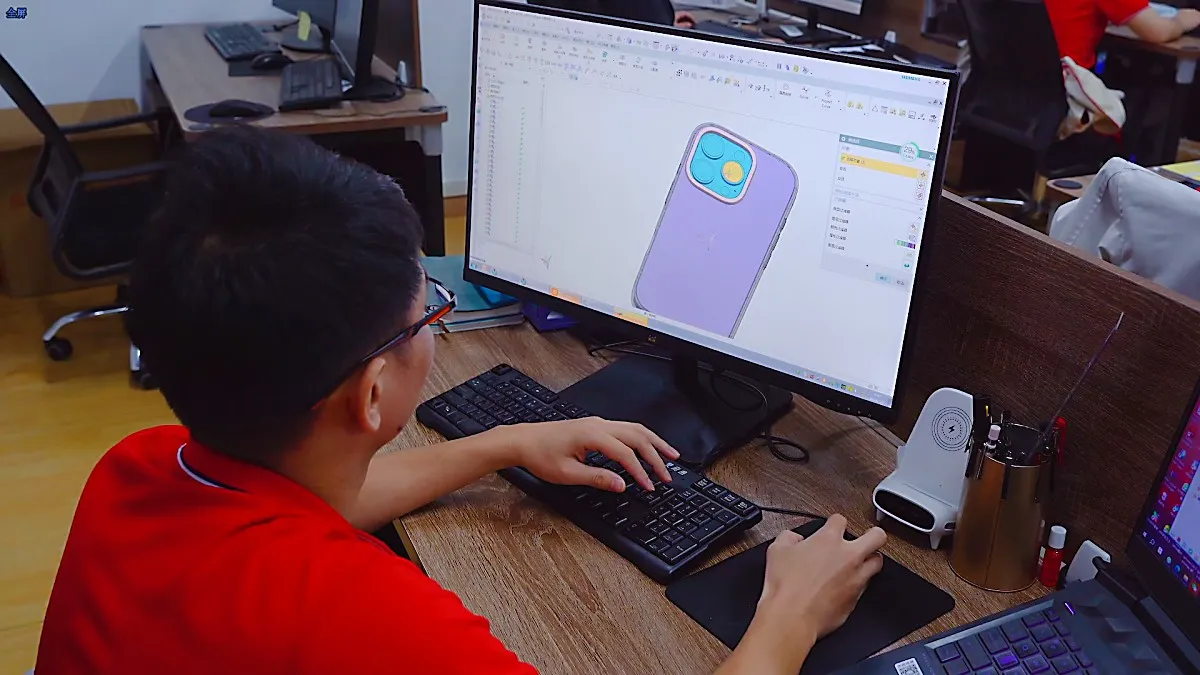

Consumer Electronics: Consumer electronics products have a short life cycle, and Rapid Tooling provides the industry with the ability to respond quickly to market changes. For example, molds for mobile phone housings can be quickly manufactured using Rapid Tooling technology to adapt to changing design requirements.

4. Rapid Tooling vs. Other Technologies

4.1 Rapid Tooling vs. Traditional Mold Manufacturing

Production Speed:

Rapid Tooling: By using rapid manufacturing technologies such as 3D printing and rapid machining, mold manufacturing time is significantly reduced. Suitable for small-volume production that requires a quick market response.

Traditional mold manufacturing: It usually takes weeks to months to design and manufacture molds, which is suitable for mass production and has obvious cost-sharing benefits.

Example: Consumer electronics companies use Rapid Tooling technology to develop molds for new products in just two weeks to seize the initiative in a highly competitive market. Traditional methods may take three months to complete the same task.

Cost-effectiveness:

Rapid Tooling: More cost-effective in small-volume production because mold manufacturing costs are lower and do not require a long development cycle.

Traditional mold manufacturing: The initial investment is higher, but it has cost advantages in mass production because the durability and long life of the mold reduce the cost per unit product.

Example: Furniture manufacturers save about 40% of mold manufacturing costs by producing limited edition products through Rapid Tooling, while traditional methods do not have such flexibility.

Design Flexibility:

Rapid Tooling: allows more frequent design iterations and modifications, suitable for industries with rapidly changing product designs.

Traditional mold manufacturing: Design changes often require re-manufacturing of molds, which is costly and time-consuming.

Example: In the medical device industry, Rapid Tooling enables a company to quickly adjust product designs to meet the latest regulatory requirements and customer feedback.

4.2 Rapid Tooling vs. Rapid Prototyping

Application Purpose:

Rapid Tooling: Mainly used to make molds, support small batch production and functional testing.

Rapid Prototyping: Mainly used to create preliminary models of products for design verification and concept testing.

Example: In toy manufacturing, Rapid Prototyping is used to verify the appearance and function of toy designs, while Rapid Tooling is used to quickly manufacture molds for trial production.

Materials and Processes:

Rapid Tooling: Typically uses more durable materials such as aluminum and high-performance plastics to withstand the pressure of the production process.

Rapid Prototyping: Typically uses resin or other rapid prototyping materials, suitable for rapid iteration and design verification.

Example: An automobile company uses Rapid Prototyping to prototype vehicle parts for wind tunnel testing, and then uses Rapid Tooling to produce small batches of actual parts for road testing.

Production scale:

Rapid Tooling: Suitable for small batch production and market testing, and can respond quickly to customer needs.

Rapid Prototyping: Usually used for the production of single or small quantities of models, mainly for internal design evaluation. For example, when developing new products, home appliance companies use Rapid Prototyping for design review, and then use Rapid Tooling for market testing to ensure the high quality and market adaptability of products before release.

Example: In toy manufacturing, Rapid Prototyping is used to verify toy designs, while Rapid Tooling is used to quickly manufacture molds for trial production.

5. Guide to Selecting Rapid Tooling Services

When selecting a Rapid Tooling service provider, companies should consider the following factors:

Technical capabilities: Whether the supplier has advanced rapid processing equipment.

Experience and expertise: The supplier’s experience and expertise in related industries.

Service scope: Whether the supplier can provide full-range support from design to production.

6. Rapid Tooling Industry Trends and Future Development

With the continuous advancement of technology, Rapid Tooling is developing in a more efficient and intelligent direction. The combination of automation and artificial intelligence will further improve the efficiency and precision of Rapid Tooling. In addition, the use of environmentally friendly materials will also become an important trend in future development, providing companies with more sustainable manufacturing solutions.

7. Conclusion

Rapid Tooling helps companies stay ahead in the competitive market by providing fast, flexible and economical mold manufacturing solutions. Whether in the automotive, aerospace or consumer electronics industries, Rapid Tooling has demonstrated its unique advantages. By choosing the right service provider, companies can fully utilize the potential of Rapid Tooling and accelerate product development and market launch.

If you are interested in more applications of Rapid Tooling or want to learn how to implement this technology in your business, please feel free to contact our team of experts. We will provide you with customized solutions to help you stand out in the industry.