It is official: YG TeCH will be exhibiting at...

Read MoreOEM/ODM

Custom Parts Manufacturing

We mainly provide services such as design, prototyping, mold making, mass production, and post-processing of complex parts. Now, upload your sketch to kickstart custom part production.

- ±0.01 mm precision manufacturing

- ISO multi-system compliance

- Stable mass production quality

- Full-process, one-stop delivery

Our Services at a Glance

Quickly sort out YG’s one-stop turnkey service for parts manufacturing, covering key links from product design to mass production, simplifying the entire parts manufacturing process for you and reducing the cost of multi-link docking.

Mold Design & Manufacturing

Customized single- and multi-cavity molds (lifespan of 500,000+ cycles), with a design turnaround time of 3-5 days, compatible with 50-600 ton injection molding machines.

Custom Injection Molding

Suitable for parts with a size of 700×850mm, with an accuracy of ±0.01mm, and covering 50+ materials including PC/ABS/PA66+GF

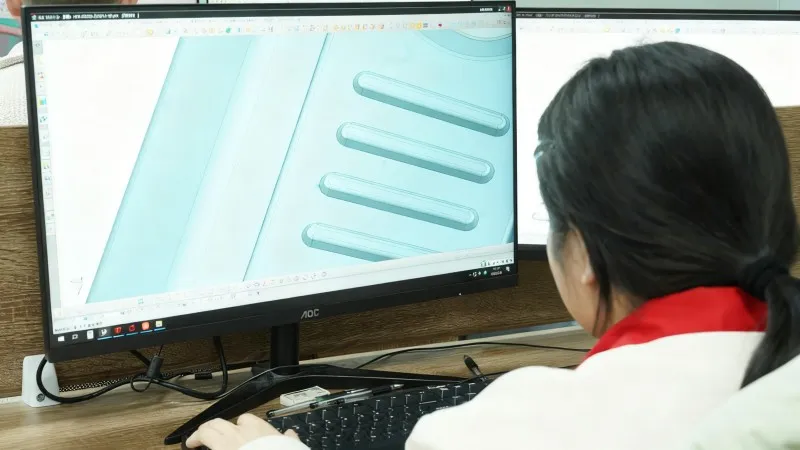

Product Design

We provide ID and MD based on your needs, DFM analysis, and compliance with industry standards such as consumer electronics and medical to help you shorten your mass production cycle.

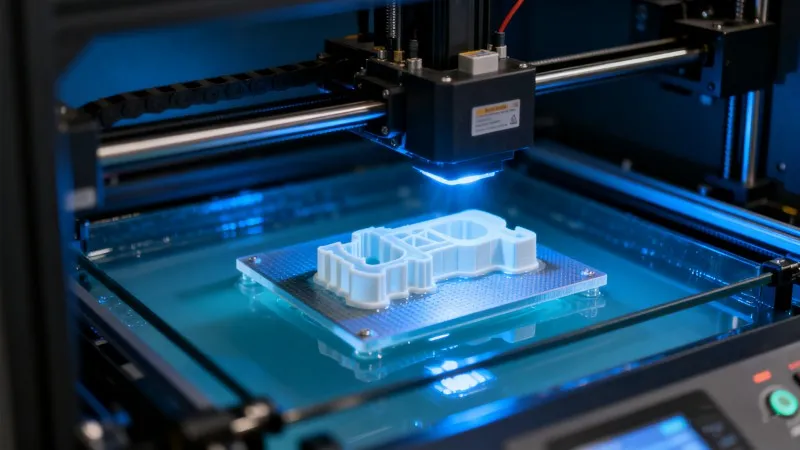

Rapid Prototyping

130+ injection molding machines, supporting complex structural parts, ±0.01mm accuracy, covering 50+ materials including PC/ABS/PA66+GF, etc.

Industries We Mainly Serve

As YG’s customer base continues to expand, we continue to enhance our professional skills and provide tailor-made solutions to more and more customers in different industries.

Why Choose YG as Your Parts Manufacturer

In parts manufacturing, you may often face challenges like “the hassle of integrating multiple links” and “high costs of mass production despite a good design.” YG customizes services based on these practical needs, helping you streamline processes, control costs, and ensure quality, making parts manufacturing more worry-free.

01. One-Stop Turnky Service

- Full-process coverage (design → mold → mass production)

- No need for multi-supplier coordination

- Proactive progress updates

02. Design-Stage Cost Reduction

- DFM analysis during design stage

- Simplify structures to save mold costs

- Replace with cost-effective materials

03. Strict Quality Control

- Pre-production mold precision scanning

- Sampling inspection for mass production batches

- Dual verification of dimensions / strength

04. Flexible Production Capacity Adaptation

- 3-day delivery for small batches

- Adjustable production for bulk orders

- 24-hour response to production capacity needs

About YG

With over 30 years of experience in the industry, YG serves customers from all industries around the world with the vision of “making people’s lives easier.” It not only provides one-stop turnkey services covering R&D, design, mold manufacturing, injection molding, finishing and post-processing, assembly, packaging, and delivery, but also helps 1,000+ customers simplify multi-link docking workflows.

We hold international certifications such as ISO9001/14001/13485, GRS, and SMETA, and meet the compliance requirements of the European and American markets. We have two manufacturing bases in China and offices in the United States and Australia to ensure stable production capacity and efficient delivery.

Dual Manufacturing Bases

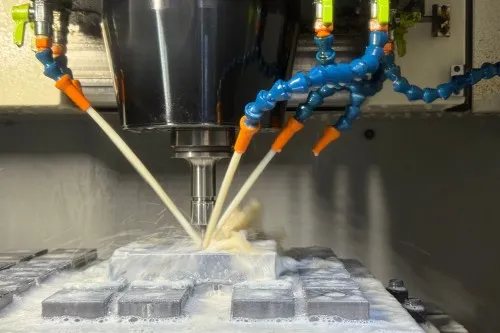

YG Manufacturing Base A – Core Mold-Making Hub

Located in Chang’an Advanced Manufacturing Park, Dongguan, with a building area of over 20,000㎡, Base A is YG’s core facility for high-end mold making.

- Equipped with high-precision CNC (Mikron, Makino) & EDM machines for complex mold fabrication

- Monthly output of 150+ sets of molds, meeting diverse mold needs (injection, precision, custom)

- 3D coordinate measuring machines (CMM) for mold dimension testing, ensuring ±0.005mm accuracy

- 10-day rapid mold manufacturing, shortening customers’ pre-production preparation cycles

YG Manufacturing Base B – Injection Molding Focused Hub

Situated adjacent to Base A in Dongguan (covering 20,000㎡), base B is YG’s core injection molding factory, focusing on stable, large-scale injection molding production to meet the finished product/component injection molding needs of customers from various industries.

- 130+ sets of machines (Sumitomo, Haitian) for varied product sizes

- Monthly output of 3 million+ injection-molded parts for bulk orders

- 30 sets of automated production lines to reduce errors & boost efficiency

- ISO 9001/13485 certified, with dust-free workstations for high-standard needs

Case Studies

Discover a selection of projects showcasing our capabilities in rapid prototyping and custom production. These case studies provide insight into the methods and technologies we employ to address specific client needs and deliver high-quality results across different industries.

Grateful for Their Trust

How to Work With YG

Upload a CAD File

Kickstart your project by uploading your CAD file. Our platform supports various file formats for seamless integration into production.

Get Quote with DFM

Quickly receive a precise quote with our DFM analysis, along with recommendations to ensure smooth production.

Manufacturing

Your product is manufactured to the highest standards in our own facilities, ensuring quality and efficiency.

Products are Shipped!

After production, we deliver your products swiftly and securely through our third-party logistics network.

Blog

YG Will Participate in

YG, a manufacturer specializing in printed and flexible electronics,...

Read More