Industrial design is an essential part of the product development process. It goes beyond the aesthetics of a product, influencing its functionality and user experience. Industrial designers combine creativity with technology and art to give products a unique vitality. In today’s competitive market, good industrial design can significantly enhance a product’s market appeal and user loyalty. Whether it’s smartphones, household appliances, or transportation vehicles, industrial design shapes our daily lives and drives technological advancements and lifestyle innovations.

Basic Principles of Industrial Design

In industrial design, several fundamental principles guide the creative process:

Functionality: The design of a product should first and foremost meet its functional requirements. A successful design should not only be visually appealing but also practical, effectively solving users’ problems. Functional design ensures that a product performs optimally and meets users’ expectations.

Aesthetics: Visual appeal plays a crucial role in attracting users. Through the clever combination of shapes, colors, and materials, designers create a visually pleasing experience. Aesthetic design is not only about visual attractiveness but also about conveying the brand’s values and concepts.

Ergonomics: Ensuring comfort and safety in product use. Designers need to consider users’ physiological and psychological needs to optimize the product’s interaction experience. Good ergonomic design can reduce user fatigue, improve efficiency, and prevent potential usage injuries.

These principles complement each other, enabling products to possess both practical value and stand out in the market. They provide a balance for designers to achieve the best possible state between functionality, aesthetics, and user experience.

Steps in Industrial Design

Industrial design is a systematic and creative process that typically includes the following key steps, each requiring careful planning and execution to ensure the success of the final product:

Needs Analysis: This is the starting point and the most critical step in the design process. Designers need to deeply understand market trends, competitive products, and user needs. Through market research, user interviews, and data analysis, a large amount of data is collected to analyze users’ pain points and expectations. Needs analysis not only helps designers clarify the functional positioning of the product but also provides important insights for subsequent design decisions.

Concept Design: Based on the needs analysis, designers begin to propose multiple design concepts. At this stage, creativity is fully unleashed, and designers explore different design directions through sketches, preliminary models, and brainstorming. The concept design phase emphasizes innovation and diversity, with designers trying out various shapes, materials, and color combinations to find the design solution that best fits the product’s positioning.

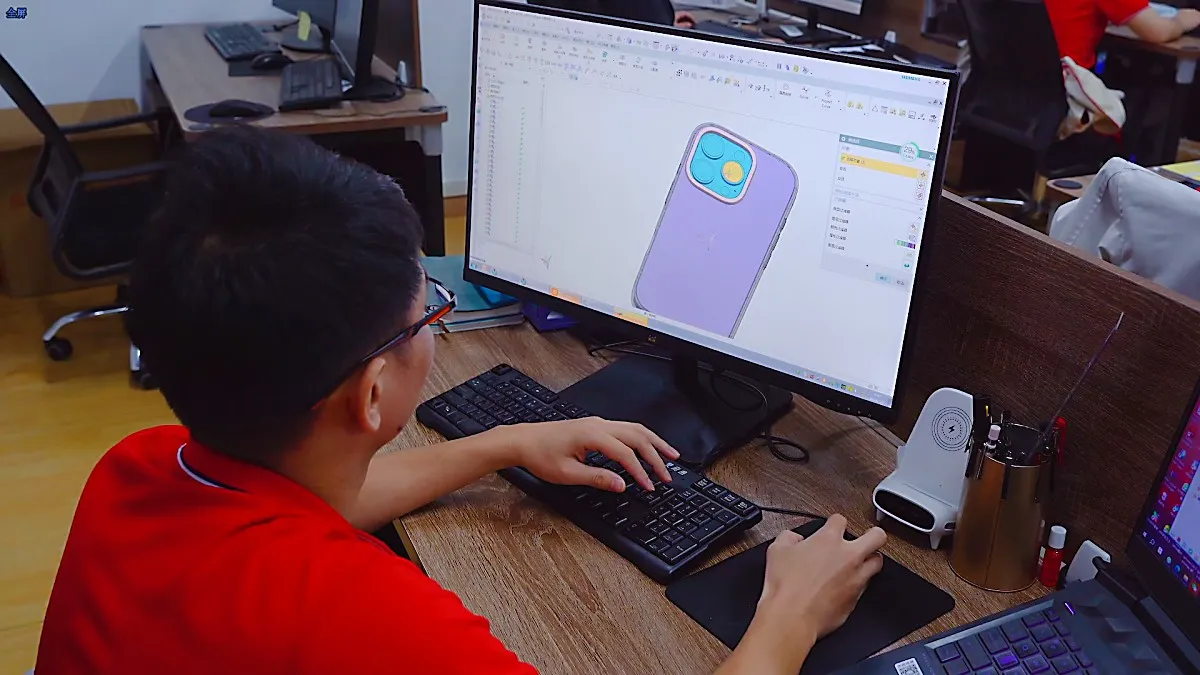

Detailed Design: After evaluation and selection, the best design concept is determined, and the detailed design phase begins. Designers need to precisely determine the product’s dimensions, materials, structure, and manufacturing processes. Detailed design requires designers to have solid technical skills and close collaboration with engineers and manufacturers to ensure the feasibility and cost-effectiveness of the design solution.

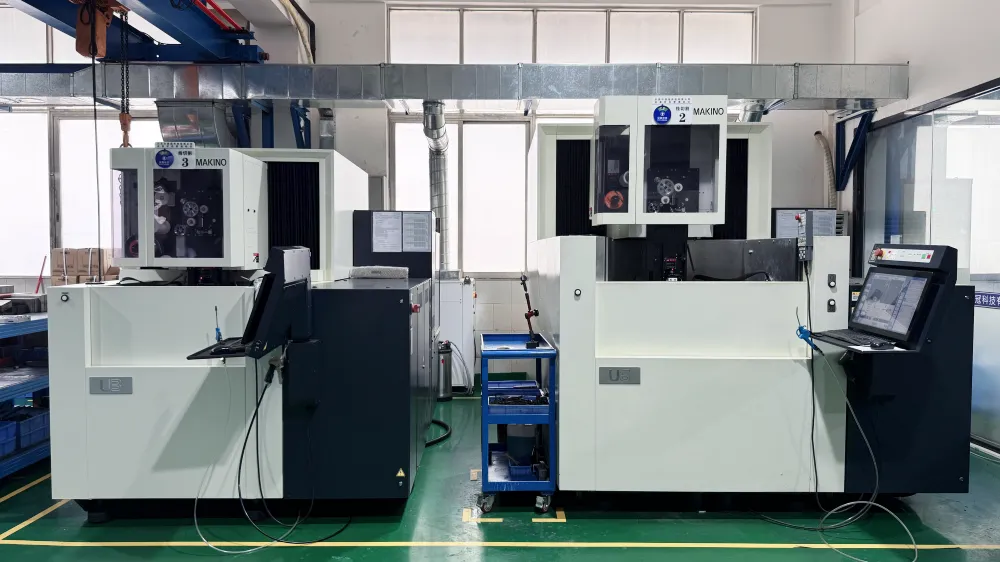

Manufacturing: The ultimate goal of design is to transform it into an actual product. The manufacturing phase requires close collaboration between designers, engineers, and production teams to supervise the production process and ensure the accurate realization of the design intent. During this process, designers may need to make adjustments based on feedback from production to address practical issues, optimize production efficiency, and product quality.

Each step is crucial, ensuring the systematic and efficient design process. Designers need to maintain good communication with all stakeholders at each stage, promptly resolving issues to ensure the smooth progress of the design project.

Industrial Design Software and Tools

Modern industrial design relies on advanced software and tools. Common design software includes:

Computer-Aided Design (CAD): Used to create precise 2D and 3D models, it is an essential tool for detailed design and engineering analysis.

3D modeling software: Such as SolidWorks and Rhinoceros, used for modeling complex shapes, helping designers test and optimize designs in a virtual environment.

Rendering software: Such as KeyShot and V-Ray, used to generate realistic product images, enabling designers to simulate the actual appearance of the design during the design phase.

Choosing the right tools can significantly improve design efficiency and quality. Designers need to select the most suitable software combination based on project-specific requirements and budget to support their creativity and design workflow.

YG Case Studies in Industrial Design

In our journey of industrial design, we have had the privilege to collaborate with numerous companies, providing them with excellent product design services. Our portfolio covers various industries and product types, including:

VR Headsets: Through innovative design and advanced technology, we have helped clients create immersive VR devices that provide users with an immersive virtual experience.

Keyboards: Striking a balance between functionality and aesthetic design, we have designed ergonomic keyboards that enhance users’ typing experience, reducing fatigue during prolonged use.

Smart Devices: We have provided design solutions for smart homes and wearable devices, making them both modern and practical, meeting users’ expectations for a smart lifestyle.

Air Purifiers: Combining environmental consciousness, our air purifier design is not only efficient but also aesthetically pleasing, suitable for various indoor environments, promoting healthy living for users.

Industrial Robots: Through modular design and user-friendly interfaces, our industrial robot design improves production efficiency and ease of operation, driving industrial automation.

Medical Devices: In the medical field, our designs prioritize accuracy and safety, providing reliable tools for medical professionals, enhancing the quality of medical services.

These successful case studies showcase how we improve a product’s appearance, functionality, and user experience through industrial design. We invite you to visit our website’s case study page to learn more about how we help clients achieve their product visions. Click the link to explore more exciting cases!

Trends and Future Developments in Industrial Design

Currently, industrial design is evolving towards sustainable design and smart products. Sustainable design emphasizes efficient resource utilization and environmental protection, with designers focusing on eco-friendliness and sustainability in material selection and product lifecycle design. Smart products incorporate Internet of Things (IoT) technology, providing more intelligent user experiences, meeting modern consumers’ pursuit of a smart lifestyle.

In the future, Virtual Reality (VR) and Augmented Reality (AR) technologies are expected to further revolutionize the way industrial design is conducted, offering more immersive design experiences. These technologies will enable designers to test and optimize designs in a virtual environment, reducing the need for physical prototypes, saving time and costs.

How to Choose the Right Industrial Design Partner

Choosing the right industrial design partner is crucial for businesses as it not only affects the design quality but also determines whether the product can successfully enter the market. Here are some key considerations:

Experience and Expertise: An excellent design partner should have extensive industry experience and expertise. They need to understand industry trends, user needs, and the latest technological developments. An experienced design team can quickly identify potential issues, provide innovative solutions, and offer professional guidance and advice throughout the design process.

Project Management Capability: Effective project management is essential to ensure projects are completed on time and within budget. Design partners should have efficient project management processes, including clear timelines, milestone objectives, and risk management strategies. They need to coordinate resources effectively at each stage of the project to ensure a smooth design process.

Innovation Capability: In a highly competitive market, innovation is a key factor that sets products apart. An appropriate design partner should have strong innovation capability and design uniqueness. They need to challenge conventional thinking, propose novel design solutions, and inject new vitality and market competitiveness into the product.

Communication and Collaboration Skills: The design process is a collaborative one involving multiple parties, and good communication and collaboration skills are the foundation of success. Design partners need to maintain good communication with clients, engineers, manufacturers, and other stakeholders, providing timely feedback and problem-solving to ensure the smooth progress of the project.

Client Reviews and Case Studies: By reviewing client reviews and successful case studies of potential design partners, you can gain a better understanding of their work style and actual capabilities. Excellent design partners usually have a series of successful cases and satisfied client reviews, which can serve as important references for selection.

Choosing the right industrial design partner not only ensures the design quality and market performance of a product but also saves time and costs for businesses while enhancing brand value and market competitiveness. Businesses should conduct comprehensive evaluations and comparisons during the selection process to find the most suitable partner that aligns with their needs and development goals.

Conclusion

Industrial design plays a critical role in product development, determining not only the appearance and functionality but also the user experience of a product. Businesses should prioritize industrial design in their product development process to ensure market competitiveness and user satisfaction. By selecting the right design partner, businesses can better realize their product visions and create stunning products. In this ever-changing era, industrial design will continue to drive technological advancements and lifestyle innovations, bringing limitless possibilities to our future.