In high-volume injection molding, the quality of a part is often determined by the fitment of mold inserts. Even a $0.01\text{mm}$ gap between inserts can lead to material flash, resulting in secondary de-burring costs and potential part rejection.

To achieve the “zero-clearance” fit required for complex consumer electronics and medical device molds, we utilize Slow-Feed Wire EDM (WEDM) as a primary finishing process.

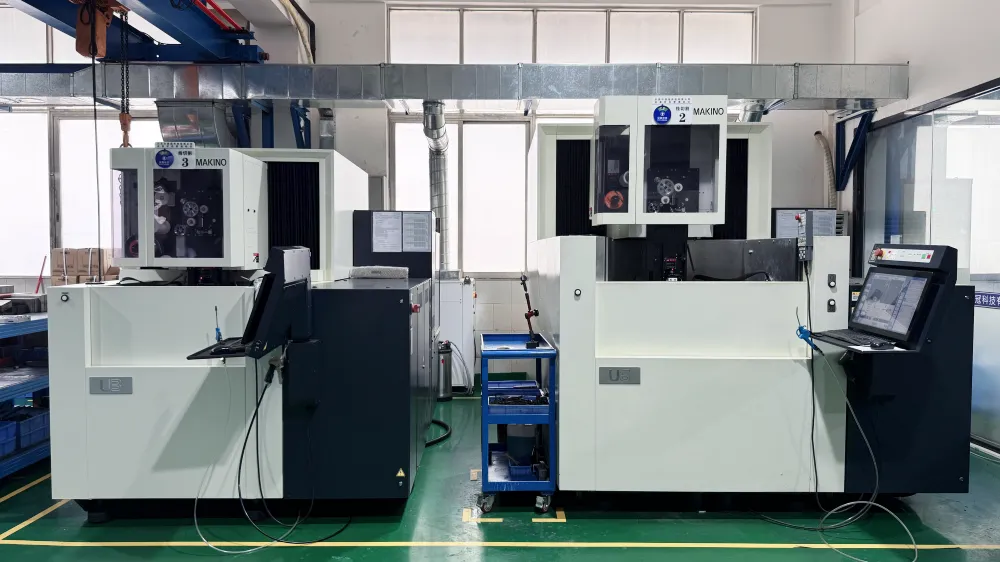

Why Makino Wire EDM?

At YG TeCH, our mold-making facility is equipped with Makino Wire EDM machines. Unlike standard wire-cut machines, these units are engineered for micro-level precision through several critical technical advantages:

Pitch Accuracy: Our machines maintain a positioning accuracy of $\pm0.002\text{mm}$. This ensures that multi-cavity inserts are perfectly interchangeable and align precisely with the mold base.

Surface Integrity: Makino’s high-frequency power supply minimizes the “heat-affected zone” (HAZ). By reducing the thickness of the white layer during the spark erosion process, we prevent micro-cracking and extend the service life of the mold.

Corner Accuracy: The machine’s wire tension control system automatically compensates for wire lag during direction changes, ensuring sharp internal corners and verticality in deep-cut features.

Managing the “Flash” Risk

The most common cause of flash in injection molding is cumulative tolerance error. If the CNC milling or standard EDM cannot hold tight enough tolerances on the insert’s mating surfaces, the pressurized plastic will find the gap.

Our Process Workflow:

Roughing + Multiple Skim Cuts: We do not rely on a single pass. By performing one rough cut followed by 3-4 precision “skimming” passes, we gradually relieve internal metal stress and achieve a mirror-like surface finish (Ra < 0.3μm).

Climate-Controlled Environment: All our precision WEDM operations are conducted in a temperature-controlled workshop to prevent thermal expansion from affecting the $\mu\text{m}$ accuracy of the steel.

In-House Inspection: Finished inserts are verified using 2.5D or CMM (Coordinate Measuring Machine) equipment to ensure dimensional compliance before they reach the assembly bench.

Technical Capabilities

| Process Metric | Achievement | Engineering Benefit |

| Tolerance | $\pm0.002\text{mm}$ to $\pm0.005\text{mm}$ | Eliminates manual fitting and flash risk. |

| Best Surface Finish | Ra 0.25 – 0.35 μm | Reduces friction during part ejection. |

| Materials | S136 (Hardened), H13, Tungsten Carbide | Process stability across high-grade tool steels. |

Engineering Advice

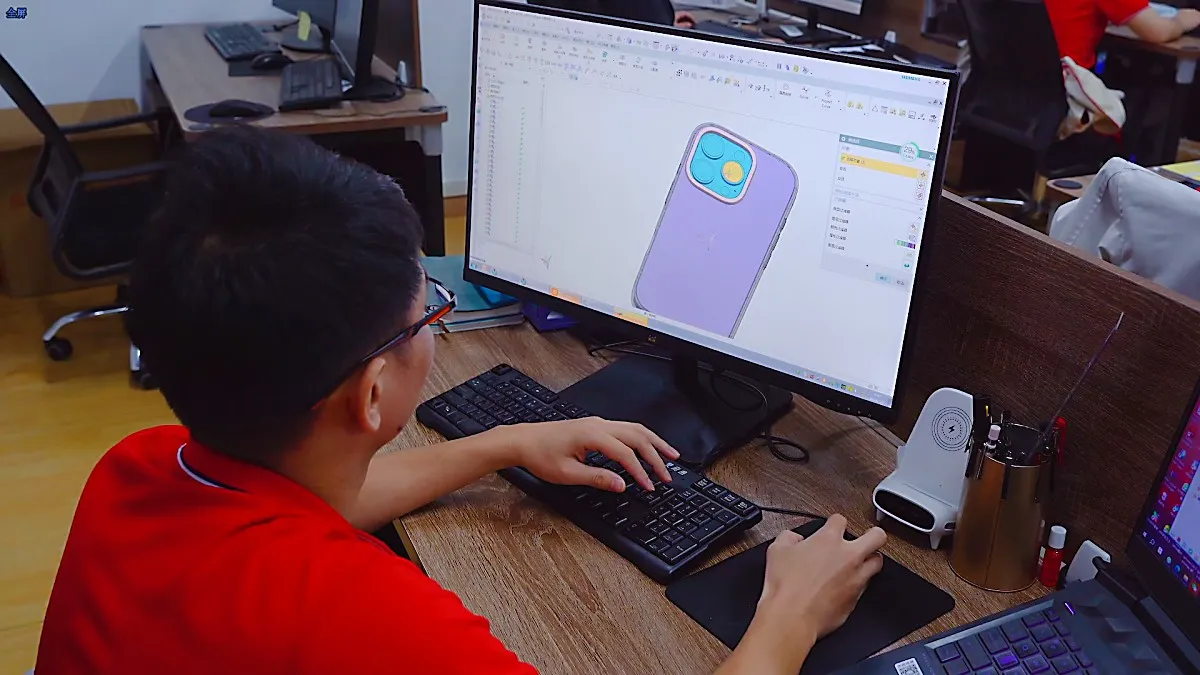

Wire EDM is a high-precision, time-intensive process. During the DFM (Design for Manufacturing) stage, our engineers will help you identify which components—such as slider cores, ejector pin holes, or narrow gate inserts—require this level of precision. This ensures you invest in high-tolerance machining only where it is critical for part functionality and mold longevity.

Do you have a project requiring tight-tolerance inserts? Contact our engineering team for a technical review of your tool design and material specifications.