When your design requires sharp internal corners or ultra-thin, deep ribs that a spindle cannot reach, Electrical Discharge Machining (EDM) becomes the necessary path forward.

The CNC Limitation: The “Radius” Problem

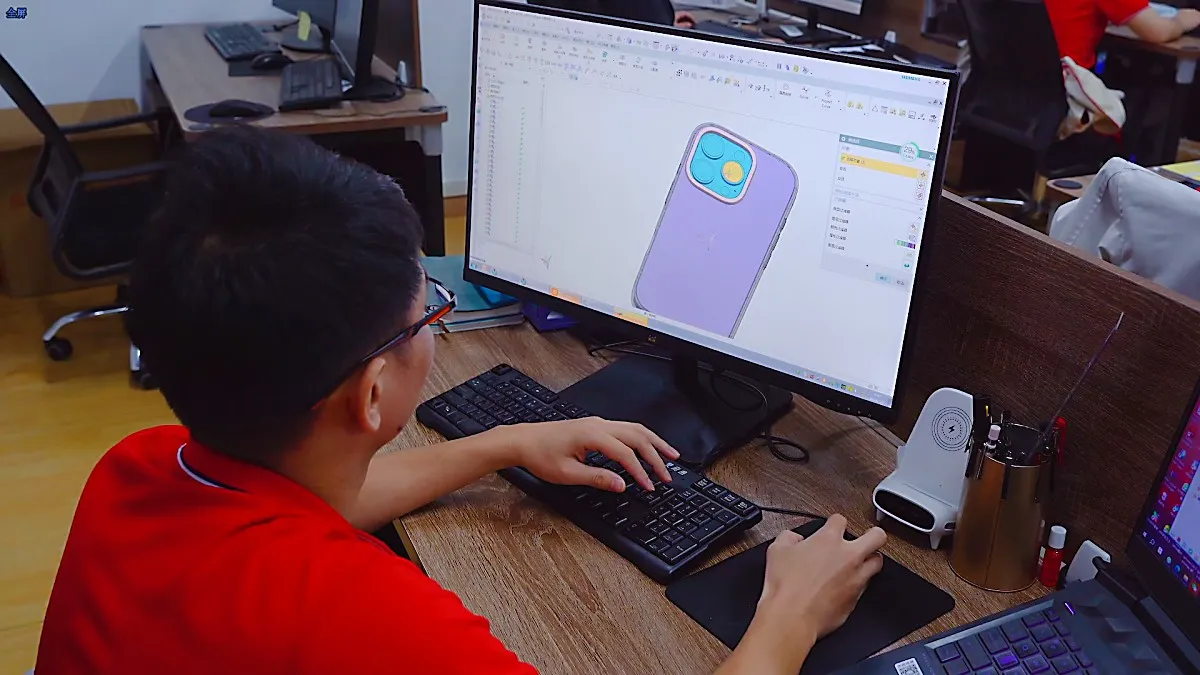

Every CNC-milled internal corner will inherently have a radius equal to the cutter’s radius. For high-precision electronic enclosures (like smartphone frames or laptop housings), a $0.5\text{mm}$ or $1.0\text{mm}$ radius might interfere with internal component fitment or compromise the intended aesthetic.

Our Approach: We utilize Sinker EDM (Spark Eroding) to “burn” the inverse shape of a copper or graphite electrode into the hardened mold steel. This allows us to achieve:

Near-Zero Radii: Sharp internal corners that are physically impossible with rotary tools.

Consistent Tolerance: Maintaining $\pm0.005\text{mm}$ accuracy across complex cavities.

Deep Ribs and Narrow Slots

Thin-walled enclosures often require deep reinforcing ribs to maintain structural integrity without adding bulk. CNC tools long enough to reach these depths are prone to vibration and breakage, leading to poor surface finishes or dimensional drift.

At YG TeCH, we optimize the EDM process for these features:

Electrode Customization: We precision-mill electrodes specifically for your rib geometry.

Controlled Flushing: Our equipment ensures constant dielectric fluid flow, preventing carbon buildup that causes “arcing” and surface defects.

VDI 3400 Standards: We deliver predictable surface textures directly from the EDM process, ranging from smooth finishes to functional matte textures.

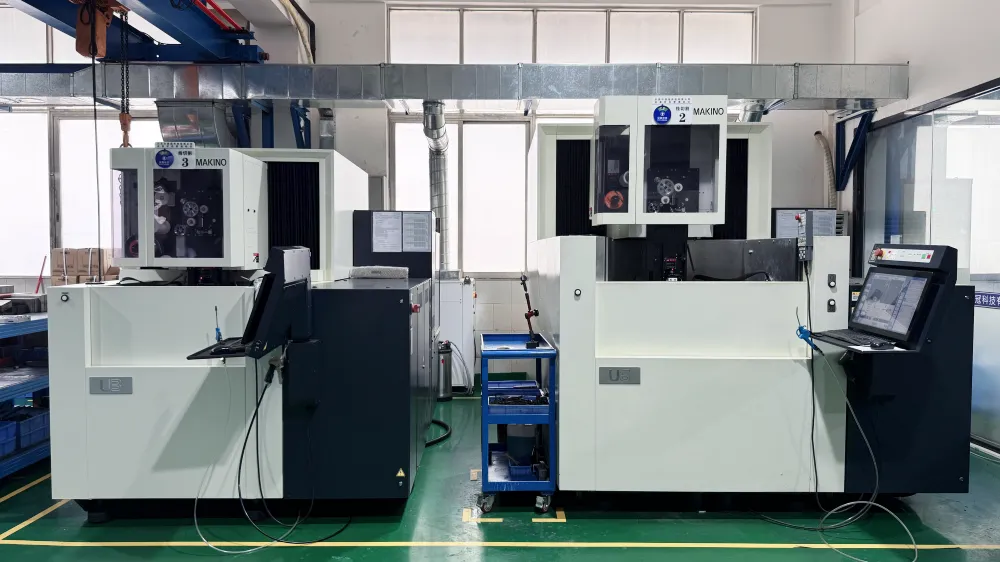

Technical Specifications at YG TeCH

To ensure project stability, our EDM department operates under the following technical parameters:

| Feature | Specification | Engineering Benefit |

| Positioning Accuracy | $\pm0.005\text{mm}$ | Ensures perfect alignment for 2K/overmolded parts. |

| Surface Finish | Ra 0.2μm (Mirror) | Reduces the need for manual polishing, preserving geometry. |

| Machine Fleet | Mitsubishi / GF AgieCharmilles | High-end Japanese/Swiss reliability for critical tolerances. |

| Material Capability | S136, H13, NAK80 | Optimized settings for high-polish and hardened steels. |

The “So What?” for Designers

We do not recommend EDM for every feature—it is slower and more costly than milling. However, for functional interfaces, snap-fits, and aesthetic sharp edges, it is the only way to ensure the physical part matches your STEP file.

During our Design for Manufacturing (DFM) review, our engineers will identify which features require EDM and suggest optimizations to minimize “burn time” without sacrificing your design intent.

Would you like a DFM checklist for your current project? Send your 3D files to our engineering team for a technical review of your rib and corner geometries.