Introduction

In today’s fast-paced market, rapid manufacturing technologies are revolutionizing the way businesses approach prototyping. This innovation is making the process faster and more cost-effective, providing companies with a competitive edge.

Advancements in Technology

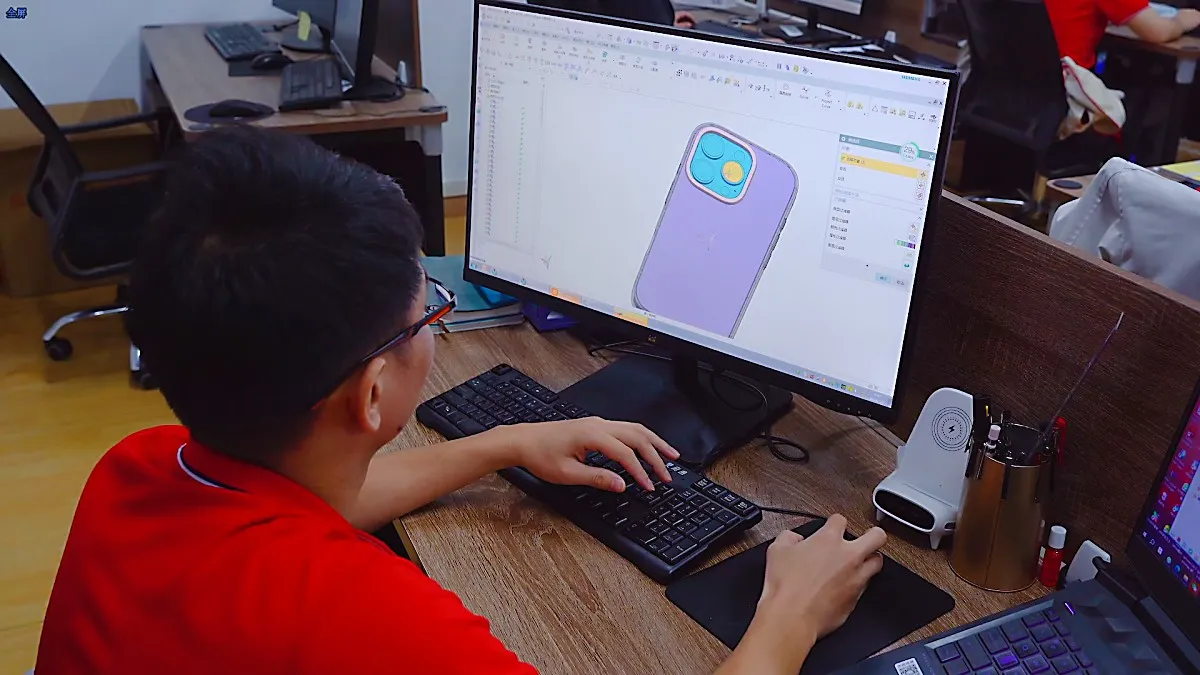

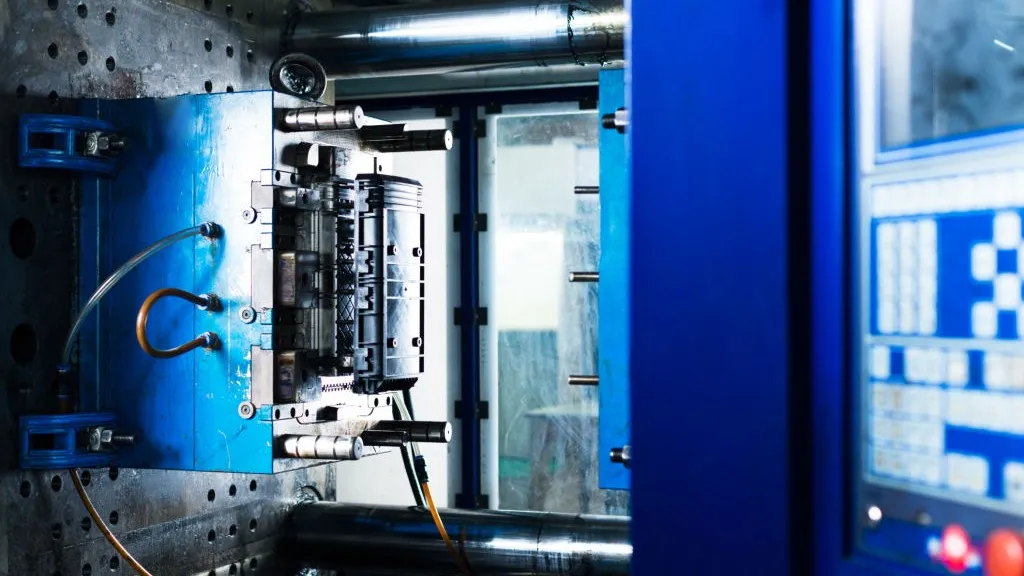

Recent advancements in technologies like 3D printing and CNC machining have transformed prototyping. These methods allow for quick iterations and precise models, enabling businesses to refine their designs efficiently. By utilizing these technologies, companies can produce complex geometries and intricate designs that were previously unattainable.

Benefits for B2B Clients

For B2B clients, these technologies mean reduced time-to-market and improved product testing. Companies can now validate their ideas quickly, ensuring they meet customer needs before full-scale production. This agility allows businesses to respond to market changes and customer feedback with unprecedented speed.

Case Study

Consider a tech startup that utilized rapid prototyping to accelerate its product launch. By leveraging these technologies, they reduced development time by 30% and improved their design accuracy. This approach not only saved costs but also allowed them to secure additional funding by demonstrating a working prototype to investors.

Practical Tips for Implementation

- Select the Right Technology: Choose the prototyping technology that best suits your product’s needs.

- Iterative Testing: Use rapid prototyping to test and refine your product iteratively.

- Collaborate with Experts: Partner with experienced manufacturers to leverage their expertise and resources.

Conclusion

Rapid manufacturing is reshaping the prototyping landscape. Businesses that adopt these technologies can expect faster development cycles and a stronger market presence. Embracing this innovation is key to staying ahead in a competitive market.