Choosing the right manufacturer is a crucial decision during the product design and development process. For a startup company, this step not only affects product quality and cost but also the speed of market launch and long-term company development. This article provides a detailed guide to help you select the appropriate manufacturer based on your company’s business, product, and industry.

Understanding Product and Industry Requirements

Product Features

1. Material Selection:

- Plastic: If your product requires plastic materials, you may need a plastic injection molding manufacturer. This process is ideal for mass production, offering cost-effectiveness and the ability to achieve complex geometries and high precision.

- Metal: For metal products, such as automotive parts or industrial equipment, look for manufacturers with metal stamping, casting, or CNC machining capabilities. Each technique offers distinct advantages—casting is great for large, complex parts, while CNC machining is perfect for high-precision components.

- Composite Materials: If your product involves composite materials like carbon fiber or fiberglass, seek manufacturers specialized in composite molding. These materials are often used in aerospace or high-performance sports equipment.

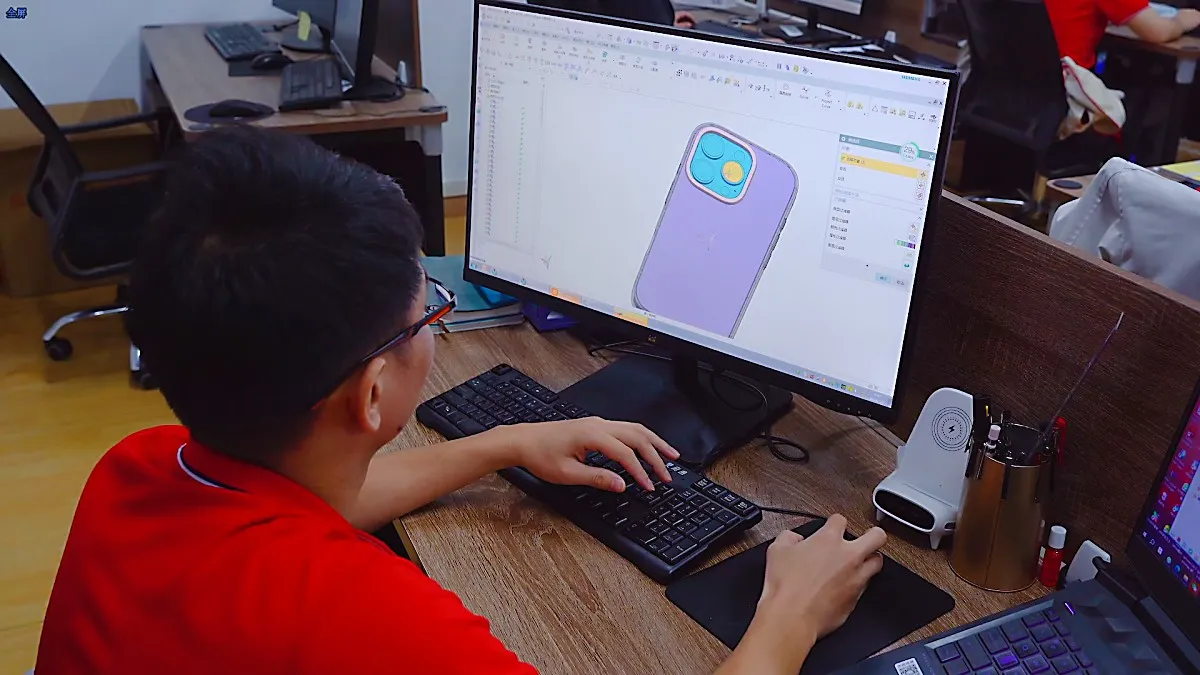

2. Design Complexity:

- Complex product designs require manufacturers with advanced technology and equipment. For example, medical device casings may require high precision and complex shapes, necessitating advanced CNC machining or injection molding services.

- For simpler designs of large batch products (such as plastic bottles), blow molding might be more suitable as it efficiently produces hollow plastic products.

3. Production Batch:

- Small Batch Production: Suitable for rapid prototyping using 3D printing or small-scale CNC machining. These processes can quickly adapt to design changes, ideal for prototype development and market testing.

- Large Batch Production: Requires efficient production processes like injection molding making or stamping to reduce unit costs and improve production efficiency.

Industry Standards

1. Compliance:

- Different industries have specific compliance requirements. For instance, the medical industry may require manufacturers to have ISO 13485 certification to ensure adherence to medical device quality management standards. The food packaging industry may need to meet FDA safety standards.

- Ensuring that the manufacturer can meet these industry-specific standards and regulations is crucial in the selection process.

2. Quality Requirements:

- Determine the product’s quality standards based on industry practices and customer expectations. For example, consumer electronics may require strict appearance and functional testing, while industrial equipment may focus more on durability and performance testing.

- Choosing a manufacturer that can provide these quality assurances can ensure the product’s success in the market.

Establishing Manufacturer Selection Criteria

Technical Capabilities

1. Process Expertise:

- Look for manufacturers with extensive experience in the production processes you need. For example, if your product requires custom injection molding, seek out companies with a strong track record in this field.

- For products needing precision machining, find manufacturers with five-axis CNC machining capabilities to ensure high precision and complex shape realization.

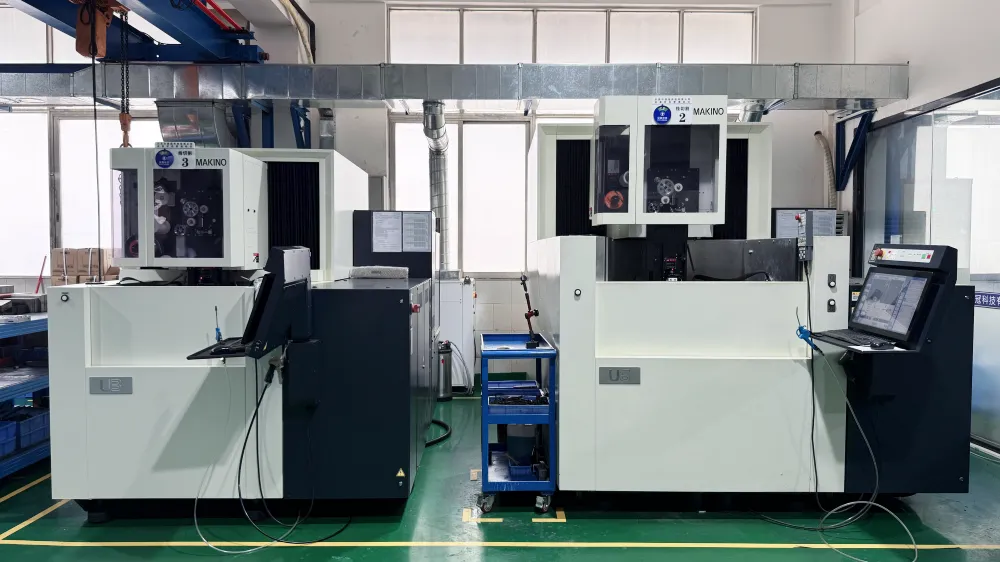

2. Equipment and Technology:

- Ensure the manufacturer has advanced equipment and technological capabilities to meet your product requirements. Modern injection molding machines can enhance production efficiency and product quality, while advanced CNC equipment can achieve higher precision and complexity.

Experience and Reputation

1. Industry Experience:

- Choose manufacturers with experience in your industry, as they will be more familiar with industry specifications and market demands. Automotive parts manufacturers, for example, typically have in-depth knowledge of TS 16949 certification and can provide products that comply with automotive industry standards.

2. Customer Reviews and Case Studies:

- Check customer reviews and successful case studies to assess the manufacturer’s reputation and reliability. Communicating with existing customers can offer valuable insights into the manufacturer’s delivery time, quality control, and customer service.

Evaluating Manufacturers

Production Capacity

1. Capacity and Flexibility:

- Evaluate the manufacturer’s production capacity to ensure they can meet your production requirements and have the flexibility to respond to demand changes. Flexibility is particularly important for startups, as market demands can change rapidly.

2. Quality Control System:

- Understand the manufacturer’s quality management process to ensure they can consistently deliver high-quality products. Check if they have certifications like ISO 9001 for quality management systems.

Cost and Pricing

1. Transparent Cost Structure:

- Obtain detailed quotations to understand cost components, including material costs, processing fees, transportation costs, etc. A transparent cost structure helps avoid hidden costs and improves budget accuracy.

2. Value for Money:

- Consider not only the price but also the quality, delivery time, and service to choose the manufacturer that offers the best value for money. Low price does not necessarily mean high value; quality and service are equally important.

Building a Partnership

Communication and Collaboration

1. Technical Exchange:

- Engage in in-depth technical exchanges with the manufacturer to ensure they fully understand your product requirements. Detailed technical communication can reduce misunderstandings and improve product development efficiency.

2. Trial Production and Validation:

- Conduct small-scale trial production to validate the manufacturer’s process capabilities and product quality. This helps identify and address potential issues before large-scale production.

Contracts and Agreements

1. Clear Terms:

- Clearly define responsibilities, delivery terms, quality standards, and confidentiality agreements in the contract. Clear contract terms can reduce future disputes.

2. Risk Management:

- Develop a risk management plan covering quality issues, delivery delays, and other potential risks. Planning risk management in advance can reduce project uncertainties.

Long-Term Collaboration and Development

Continuous Evaluation

1. Regular Assessment:

- Regularly assess the manufacturer’s performance and adjust the collaboration strategy as needed. Continuous evaluation helps maintain a high-quality partnership.

2. Innovation and Improvement:

- Collaborate with the manufacturer to explore new processes and technologies for continuous improvement of products and processes. Innovative collaborations can bring competitive advantages.

Relationship Maintenance

1. Communication Mechanism:

- Establish regular communication mechanisms to maintain a good working relationship. Effective communication enhances trust and improves collaboration efficiency.

2. Mutual Growth:

- Choose manufacturers willing to grow with your company and support your long-term development goals. A mutually beneficial partnership contributes to win-win outcomes.

By following these steps, you can systematically choose the right manufacturer to ensure successful product development and market launch. I hope this guide provides valuable assistance to your startup company.