Introduction

In the rapidly evolving world of manufacturing, automation and artificial intelligence (AI) are no longer just buzzwords—they are essential components driving the future of the industry. For B2B companies, understanding and leveraging these technologies can unlock new levels of efficiency and innovation.

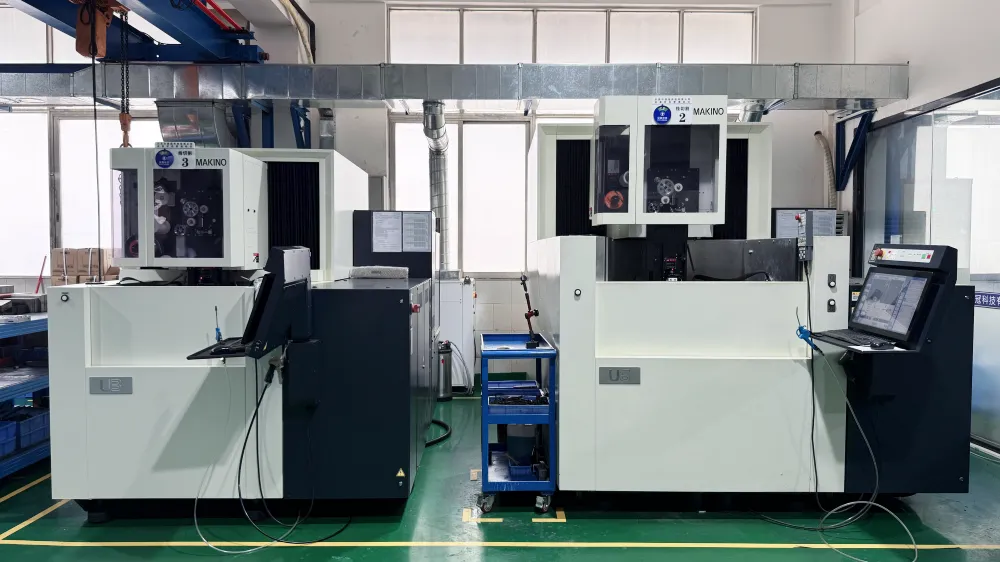

The Rise of Automation in Manufacturing

- Increased Efficiency: Automation reduces human error and accelerates production processes, allowing manufacturers to meet tight deadlines and handle larger orders without compromising quality.

- Cost Reduction: By automating repetitive tasks, companies can significantly cut labor costs and redirect resources towards strategic initiatives.

- Scalability: Automated systems can easily adapt to changes in production volume, providing flexibility to meet market demands.

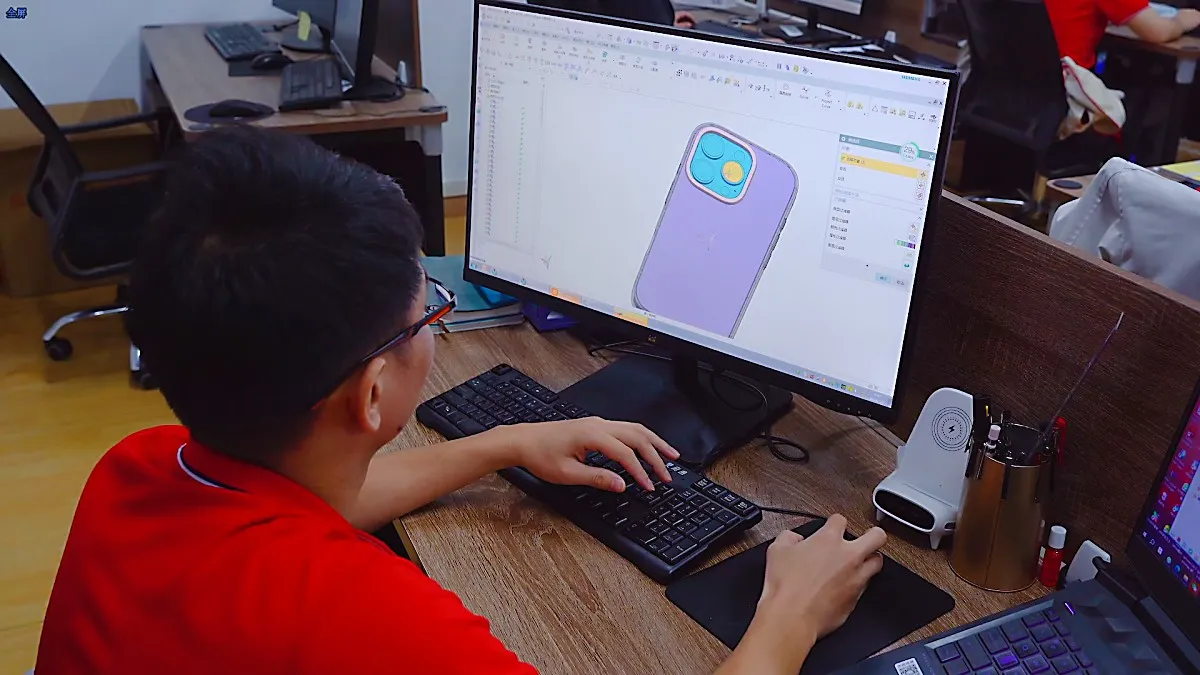

AI's Role in Manufacturing

- Predictive Maintenance: AI algorithms analyze data from machinery to predict failures before they occur, minimizing downtime and maintenance costs.

- Quality Control: AI-powered systems can detect defects with higher accuracy than human inspectors, ensuring consistent product quality.

- Supply Chain Optimization: AI helps in forecasting demand and optimizing inventory levels, reducing waste and improving customer satisfaction.

Case Study

Highlight a company that successfully implemented automation and AI, leading to significant improvements in efficiency and cost savings. For example, a manufacturer that integrated AI-driven predictive maintenance saw a 30% reduction in machine downtime.

Conclusion

Embracing automation and AI is no longer optional for manufacturers looking to stay competitive. By integrating these technologies, B2B companies can achieve greater efficiency, reduce costs, and drive innovation. The future of manufacturing is here—are you ready to embrace it?